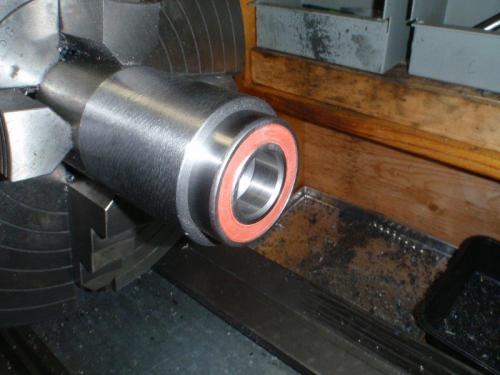

I spent some time today making the bearing carrier for the spindle. I really need to get some more tapered-shank drill bits. They are the best way to drill large holes on the lathe.

The usual boring work to make the through-hole and the two pockets for the bearings. I managed to sneak up on the pocket diameters for a press fit on both bearings.

The fit was tight enough that the arbor press wouldn't quite do it, but the hydraulic press had no trouble at all.

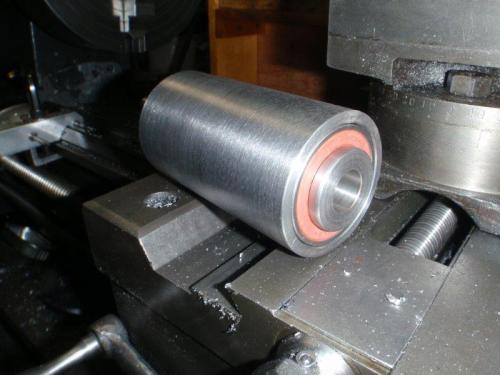

I figured I'd better check the runout, so I set it up as shown. Unfortunately, there is about 0.006" TIR. I'll see what I can do to improve that. It's possible that the economy bearings have some runout.

The usual boring work to make the through-hole and the two pockets for the bearings. I managed to sneak up on the pocket diameters for a press fit on both bearings.

The fit was tight enough that the arbor press wouldn't quite do it, but the hydraulic press had no trouble at all.

I figured I'd better check the runout, so I set it up as shown. Unfortunately, there is about 0.006" TIR. I'll see what I can do to improve that. It's possible that the economy bearings have some runout.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.