10-26-2015, 06:58 PM

I have no idea what has gotten into me. I actually completed another back burner project. Must be the new drugs

Most of my adventures begin with "A long time ago I started ...". This is no different. I acquired a Harbor Freight parts washer and before I actually used it I decided I need to improve it. I replace the legs and shelf with something more robust, then made some improvements to the pump and solvent process, then something came along and the project was sidelined.

Over the weekend I ran across the parts washer so I thought I'd direct my efforts to that last 10% and finish it up.

The more robust stand is made from angle iron with an expanded metal shelf and the casters. There is a switch box on the front which control matching outlets in the box directly behind the switch box. One switch is for the pump that is in the bottle, one switch if for the light ... future project .... one for the heater ... future project ... and one for the agitator ... future project.

Here you can kinda see the plumbing. I wanted a valve on the bottom of the basin rather than just a drain plug. The drain plug was some metric threading so I had to drill out the bung in bottom of the basin and retap it with regular pipe threads. I could then thread in a NPT-to-copper adapter and then solder the valve and hose fittings that go into the catch bottle.

It also shows the block off plate I made to go where the pump was originally mounted. Normally all the fluid is in the basin and the pump is mounted on the inside of the basin. It pumps the fluid from the basin into the hose. I (a) wanted to use something other than water based fluids so I had to get a different pump anyway ... the one that comes with it will melt after a couple of months of exposure to any non-water based fluids and (b) I did not want the fluid to just sit in the bottom of the basin. Hence the drain modification and the catch bottle.

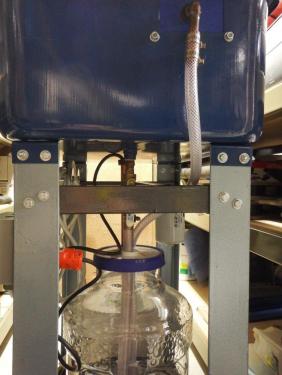

The catch bottle is a 6.5 gallon jug used for making beer at home. I think it is called a bubbler or something like that.

The back shows the mineral spirits and a much more powerful pump suspended on a copper tube a few inches off the bottom of the catch bottle. There is a gallon of water in the bottom of the catch bottle and then maybe 2 - 3 gallons of mineral spirits on top of it. You can see the line between the two liquids. The heavy crap should settle to the bottom of the catch bottle. The water just adds volume to the area where the crap can build up but does not cost nearly as much as the mineral spirits. The light crap should be trapped by the oil filter on the way into the basin.

When enough heavy stuff builds up at the bottom of the catch bottle I will close the drain valve and allow the pump to push all but the last couple of inches of mineral spirits up into the basin. I can then remove the catch bottle, dump it out and clean it, put another gallon [or maybe more] of water in, turn on the drain and only need to add a gallon of mineral spirits to make up for what I will loose in the cleaning process.

This is the inside. I used the block off plate in the spot where the old pump went as my entry point. I then soldered together some fittings that would control the flow to the spout and the parts brush. A couple of little baskets to hold stuff ... one of them is actually for making tea! ... and I think I'm good-to-go.

Most of my adventures begin with "A long time ago I started ...". This is no different. I acquired a Harbor Freight parts washer and before I actually used it I decided I need to improve it. I replace the legs and shelf with something more robust, then made some improvements to the pump and solvent process, then something came along and the project was sidelined.

Over the weekend I ran across the parts washer so I thought I'd direct my efforts to that last 10% and finish it up.

The more robust stand is made from angle iron with an expanded metal shelf and the casters. There is a switch box on the front which control matching outlets in the box directly behind the switch box. One switch is for the pump that is in the bottle, one switch if for the light ... future project .... one for the heater ... future project ... and one for the agitator ... future project.

Here you can kinda see the plumbing. I wanted a valve on the bottom of the basin rather than just a drain plug. The drain plug was some metric threading so I had to drill out the bung in bottom of the basin and retap it with regular pipe threads. I could then thread in a NPT-to-copper adapter and then solder the valve and hose fittings that go into the catch bottle.

It also shows the block off plate I made to go where the pump was originally mounted. Normally all the fluid is in the basin and the pump is mounted on the inside of the basin. It pumps the fluid from the basin into the hose. I (a) wanted to use something other than water based fluids so I had to get a different pump anyway ... the one that comes with it will melt after a couple of months of exposure to any non-water based fluids and (b) I did not want the fluid to just sit in the bottom of the basin. Hence the drain modification and the catch bottle.

The catch bottle is a 6.5 gallon jug used for making beer at home. I think it is called a bubbler or something like that.

The back shows the mineral spirits and a much more powerful pump suspended on a copper tube a few inches off the bottom of the catch bottle. There is a gallon of water in the bottom of the catch bottle and then maybe 2 - 3 gallons of mineral spirits on top of it. You can see the line between the two liquids. The heavy crap should settle to the bottom of the catch bottle. The water just adds volume to the area where the crap can build up but does not cost nearly as much as the mineral spirits. The light crap should be trapped by the oil filter on the way into the basin.

When enough heavy stuff builds up at the bottom of the catch bottle I will close the drain valve and allow the pump to push all but the last couple of inches of mineral spirits up into the basin. I can then remove the catch bottle, dump it out and clean it, put another gallon [or maybe more] of water in, turn on the drain and only need to add a gallon of mineral spirits to make up for what I will loose in the cleaning process.

This is the inside. I used the block off plate in the spot where the old pump went as my entry point. I then soldered together some fittings that would control the flow to the spout and the parts brush. A couple of little baskets to hold stuff ... one of them is actually for making tea! ... and I think I'm good-to-go.