WOW??? Am I all behind with this thread

So the next part to make was the ignition timing wheel. really this is a twin to the cam timing gear without teeth. it will have a small magnet fixed in the rim to operate the ignition ,

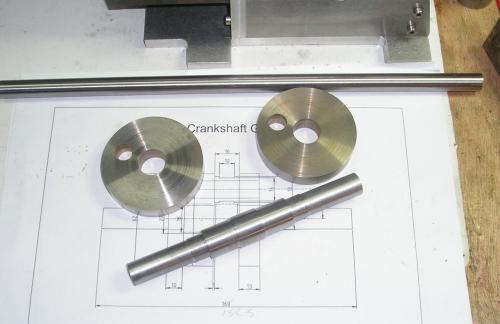

The arrival of the material got me started on the main shaft for the crank to keep every thing in line. this has to be machined between centres. this has the advantage that you can turn one end.

then flip it over and do the other without worrying.

The shaft was made .25mm oversize on all dimensions. for starters.

The crank webs were roughed out on the lathe and then transferred to the mill to bore the centre.

this then allowed me to move 20mm to one side and bore the hole for the big end pin.

doing it this way nothing had to be marked out.

The pin to take the big end was made and the shaft bought to size then a trial assembly done.

This will be put to one side while I make the flywheels.

Phew up to date.

Brian.

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)