Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Well that is nicely done Brian

. Did you harden the gear cutter?

DaveH

Posts: 437

Threads: 24

Joined: Sep 2012

Location: Sicily

Hi Dave the cutter was made from silver steel (Drill rod ) hardened and tempered. works a treat If you take light cuts.

I make clock gears with this type of cuter, it will cut a tooth in 1/8" brass at one pass, the teeth on clock gears are a lot longer the involute gears so the cutter is a little more delicate, but works just fine.

Brian.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Thanks Brian, it looks like it worked very well

DaveH

Posts: 437

Threads: 24

Joined: Sep 2012

Location: Sicily

Not a lot done today, been at the Doc's all morning.

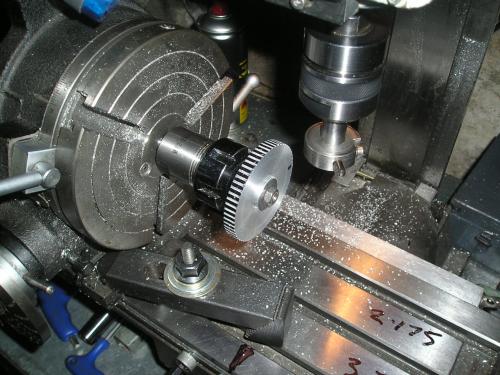

Started on the camshaft gear

Turning the blank. I can even turn the back of the blank now after modifying the 7x12 ??

Taking the first cut on the mill. note how blueing the edge helps.

that's all for today

Brian

Posts: 437

Threads: 24

Joined: Sep 2012

Location: Sicily

The following 1 user Likes Brian's post:

EdK (10-28-2014)

Well this is it setup on my depthing tool that I use for clock gears, it runs a treat with it's mating pair, only the crankshaft gear to do to make the set.

Brian

Posts: 437

Threads: 24

Joined: Sep 2012

Location: Sicily

The following 1 user Likes Brian's post:

Mayhem (10-30-2014)

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

how are you going to do the rings for the piston,

DA

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

Posts: 437

Threads: 24

Joined: Sep 2012

Location: Sicily

Hi Dallen

The engine was designed from the start to take the rings from a weed cutter, so I have no problems in that respect.

Brian.

Posts: 437

Threads: 24

Joined: Sep 2012

Location: Sicily

The following 4 users Like Brian's post:

EdK (11-04-2014), f350ca (11-04-2014), DaveH (11-04-2014), Mayhem (11-04-2014)

Just ordered the material for the crank --flywheels ETC.

So I will get on with the cam redesign I originally was going to make the rockers from bronze with flat cam follower but I think that the inertia of these relatively large rockers may be to great for the valve springs, so I have changed to alloy rockers with roller followers.

All well and good but the original flat followers initially lift at the tips of the cam and the rollers lift at the base circle this makes the rollers slower to respond and more affected by valve clearance.

So I have cut a cam that I think is ok and made a test rig to determine the point of initial lift so I can get the profile correct.

Slowly slowly.

Brian

. Did you harden the gear cutter?

. Did you harden the gear cutter?