Posts: 3,798

Threads: 184

Joined: Jun 2012

Location: Farmington Hills, Michigan

Plastic has its place, but that's definitely not one of them. Nice job Brian, it never hurts to add a few extra Brownie points.

Tom

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

05-10-2013, 03:31 PM

(This post was last modified: 05-10-2013, 03:36 PM by stevec.)

Whoa! Ang on, ang on.

What material did you use Brian?

I mean, is it aluminum and you were able to send to Tom for internet anodizing?

Or maybe some kinda Sicilian silver?

No, I'll bet you have a 3-D printer?

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 8,859

Threads: 319

Joined: Feb 2012

Location: Arizona/Minnesota

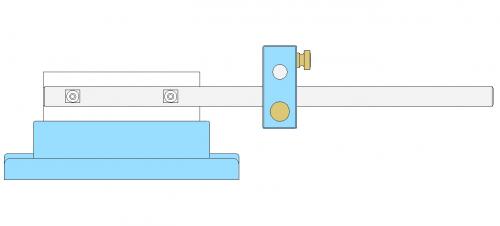

I worked on the work stop for my vise. The rod that is bolted on to the back of the vise is just hardware store zinc plated 1/2" mystery steel. The two blocks are made from some 7/8" 12L14 that I had laying around. Next is to make the brass clamps and then chamfer the edges of the blocks to make them look pretty. I think I'm going to paint the blocks to match the vise.

Ed

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

took all the screws out of this and watched it fall apart in my hands

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

Posts: 437

Threads: 24

Joined: Sep 2012

Location: Sicily

(05-10-2013, 03:31 PM)stevec Wrote: Whoa! Ang on, ang on.

What material did you use Brian?

I mean, is it aluminum and you were able to send to Tom for internet anodizing?

Or maybe some kinda Sicilian silver?

No, I'll bet you have a 3-D printer?

It's Hi grade scrap steel from a old balcony, Steve. Painted with with a auto selected finish ( the first spray can on the shelf )

Real Hi Tech not for the faint hearted to attempt.

Brian.

when you say your Gran then your mom owned one that will go on for generations to come before anything wears out

when you say your Gran then your mom owned one that will go on for generations to come before anything wears out

when you say your Gran then your mom owned one that will go on for generations to come before anything wears out

when you say your Gran then your mom owned one that will go on for generations to come before anything wears out

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)