Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

Not going to get me the kudos of putting in a new kitchen, but I've spent a bit of time on my toolholders.

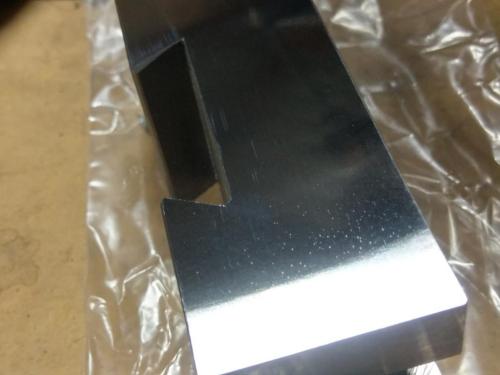

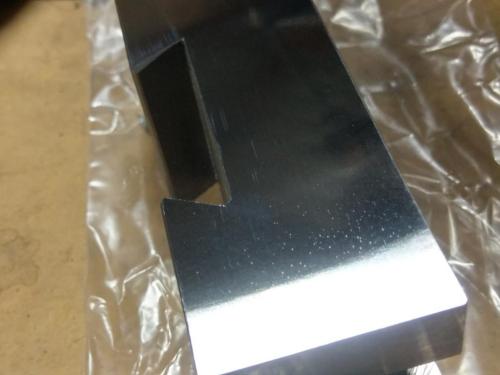

Used a horizontal cutter to carve the slots

then swapped the horizontal arbor for a face mill and milled the ends in the Y axis.

so now I have a heap of holes to drill and tap.

It occured to me that I can do the drilling and tapping in the Y axis as well, I have a keyless chuck on a NT40 arbor to fit the main spindle. Will save me mounting the vertical attachment and as the attachment doesn't have a quill it shouldn't be any more difficult anyway.

I've also had a bit of a play with the new surface grinder, having got it all set up and wired in. Started with a little piece of scrap unknownium:

then decided to grind a surface on one of the toolholder blanks. I was pretty chuffed with how it came up.

I think I'm going to have to put a ground finish on all of them now. Cos I can.

Still hoping someone can answer my question about the dust collector on the grinder. Google has been no help. Until I hear different, I'll be running it dry.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 3,798

Threads: 184

Joined: Jun 2012

Location: Farmington Hills, Michigan

It's been a lot of years since I last ran a horizontal mill, but I've always been impressed at how useful they can be.

It must be nice to have a surface grinder at your disposal. I'm hoping to add one soon to my shop.

Nice start on the tool holders.

Tom

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

Nice finish from the grinder Pete! A few things here have been getting a ground finish as well, just cause I can. If there was no sign of water ever being in the dust collector it may have been designed to run dry, but the water table under my plasma cutter traps pretty much all the dust from it.

Free advice is worth exactly what you payed for it.

Greg

Posts: 8,854

Threads: 318

Joined: Feb 2012

Location: Arizona/Minnesota

Got some PVC pipe to hold stock 3ft and less. Kind of sorted by material type.

Ed

Posts: 2,618

Threads: 100

Joined: Dec 2014

Location: Michigan

The following 2 users Like Vinny's post:

EdK (05-31-2017), f350ca (05-31-2017)

(05-31-2017, 03:03 AM)Pete O Wrote: so now I have a heap of holes to drill and tap.

It occured to me that I can do the drilling and tapping in the Y axis as well, I have a keyless chuck on a NT40 arbor to fit the main spindle. Will save me mounting the vertical attachment and as the attachment doesn't have a quill it shouldn't be any more difficult anyway.

Actually you should put them in a box, put the box in your truck and drive over to Greg's and use his new drill press. Pack a lunch, it may take ya a couple hours to get there.

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

The following 1 user Likes f350ca's post:

Pete O (06-01-2017)

B een too busy in the cabinet shop Vinny. Still haven't got it powered up. But drop over anyway Pete, if you decide to come Im sure I can get it going before you get here.

Free advice is worth exactly what you payed for it.

Greg

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

The following 1 user Likes f350ca's post:

Mayhem (06-01-2017)

Had to buy this lumber, its a maple countertop in kit form. Some assembled required.

![[Image: 4ePT3mtefdEtkbb69GFXW0hD1aV2qtTiAHQvOARe...7-h1276-no]](https://lh3.googleusercontent.com/4ePT3mtefdEtkbb69GFXW0hD1aV2qtTiAHQvOARe8DnATBU_I5wiqOHSx5iYpzgOOsjkD5Pyzj3iHD74KdGvQSIk_Vd7ECHjzMiMVk2tLB-swyf7MAz4FkzZeOXy0M05k3AiLr65P8QYTOw9BuIKSJALkC7zLFDrIi0GnxrvAO44YZCMgF2YxpiTxW0Gb6_2870uaGVUH12G05vb1k-0NAqct4dsPUHVbssCPXA0LUZRpv7KbTMh4ayCZsj9TRWyxrNlwwkADEJXF73o8_2X6G7T1grgAaXrnv1V2-8iPZI6bbKYAo9oqDfxSuRyqYB6JALQmNp9qI1evACX6OovrzcbC0gTZbJmGACYOIpdZ73yUTBkSjTKRkSO9KDyR2lOjfBEvf7sZ05RBvFCwQ1gjObpumy0D5jUugrJ2OwgrIaK43bgllDD_pteE3pNamqfkuw6NSL2NtUM6Z94tQx1f1kMtX2a52yiWa3Zy3PQzcISc_04-P4qZWyhyxIUbMxSNGA5jhl50TvAhS6JFnFYcypynPuTrG4O2ExYMP5k72x1jKEqnwHJzancTHRq889p_6Fg4f-qsXZTo7fcrDPlbfyk9XalIrD3MQ-lTJIIFGa30AXlVpRI=w957-h1276-no)

It gets ripped into 1 3/4 strips, but I need a straight edge to start from. The first one I cut with the skill saw following a chalk line, then that one gets used as a rip fence for the rest.

![[Image: Ea3XK-9U09B_0uRLJOx1D3sUaygv6rldNblP9k6i...7-h1276-no]](https://lh3.googleusercontent.com/Ea3XK-9U09B_0uRLJOx1D3sUaygv6rldNblP9k6i2M3MvKmpkNce7YcP53F3w6l9ZQJOB4R5ovwtbD_ddAaMizh3cneGfe4z_q9B_ygQfxvSuwYdW_Fi6WNqHz_3YpdD0e8uBytjr6X0nf5krSSUWoKNu-cAU7XycEfJeshwH5lfPxpdNKELSU7mEWJ9QibhnLckAnjHW6ymS9hSgvfNo9vEa-Qb-Y_n7qhRG-hfDVPjrVyakveb9IBv6XLYm5nukHdIDOGtKbtjzo-qKCJwzIiuDtOYgm3Ii9JBswgwzz_Bgnh8Md63lodTnu6XlMMzZxWthM5K4cC3MkDqNQ-ajGRFzgbv2UVb6GJFDD_ICVxb-cw7_M-cxlC5HXnqYjPOV3a0ABEZcJHRjSv2AtBAQc2dHtILoFRmy9Bccw_eKSZcVzEcdjzDSN24RzQP5AnkKixSsL8qi8eTHVesyaC09PkFmP1ug9uZvx_4heQVwDyciDftGh91e4JS_GFERepLw6ZzN91tMSCnq6UrYYx5oN-ZVAD9J-6zCxvXyd5OrRd5dTn17hwEYkYKANBY8xLtaGfJKXZeNjXxrsfDXJFugopdmJnRxoYgEFqkTXxVVUkVT4x4IKqm=w957-h1276-no)

Then they get planed to get smooth edges for glue. This is just a dry fit, add glue tomorrow.

![[Image: HFPyGdIlJdjkW-6_yqqMScA5MsS7KEFLGZgQHO5D...7-h1276-no]](https://lh3.googleusercontent.com/HFPyGdIlJdjkW-6_yqqMScA5MsS7KEFLGZgQHO5DOKTSVgIAhgP71DvrWREmwCx-b0LhZ3-V4TvuzeDHM56RNiwATkiGN5UrRgb0Ec_GDzWX86NTWjGd_m9S32JV2Ff_m2QzHog-K3uKWm6FPjFU5JGevBr1QHb1-1X0B9NSa8OUw0Lf-8frNuWMHrunw7c-GbGtfV17eIxJwx7Y5vy-e2Rhw7TtFuPqkAy8bdjbqEvmHarXtb6MytobM0nxRiW77eRUtuPwq5krot1Z7JHGCrRWhrGclHGBu0E21OvV7Eay7Ai--9pN2PxogPBUuTtro3TiKH4M6E80nfP9iJdTlKygiRTpKoEVLPm3kT718jIMDD1EkL_wS-aeJl7IKgOH0UVioJofIYaUNl6rhCpx4N-jKou1wgES4YywNVn5I52VMbJzDp4CzmTFdl4pAZh3gKTKvtzK2dB-7sd3qyUDsdIRHjiTnk4g_ie57bjr5aGRbjgl_zqnioDxtidh9_w5iKErLAU2yBeMAf5R3DcTbAJLAk_jllRE6-E6qmE95j43WTia9nsO_OVgJr1drHdmT_Mm2w-g_u1mgPCZQjctZwNDAoZXTcPJ5K5fLQiSteW8k2poAK9h=w957-h1276-no)

Free advice is worth exactly what you payed for it.

Greg

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

On another floor progress is slow on the drill press. Steal a bit of time now and then.

Cut the sides of the enclosure for the vfd from a shelf that once was in a filing cabinet. The plasma table makes sheet metal work a whole lot easier.

![[Image: LDB5dg3PMyX-yDYy4uWQtojkIu1Kyp0t5YTdX3_X...99-h398-no]](https://lh3.googleusercontent.com/LDB5dg3PMyX-yDYy4uWQtojkIu1Kyp0t5YTdX3_XHmPJQgsmU8t1f1VY-c5Y4EnImoOiUtsf6KLtMIUUlNX8lIrcl4HsUPzW6z7xBFpGJeE5nV5V2M0pToCBcQHGWayTaTISQX6zCIbb9Ma7cwMYATdYEFnKaD8EmYHT3rXjhwT_YRyFhkecqHkqoCQBUWSsOPj5wt0I0M7A54WRqd8lLVjb8JvUta_uueX1ywPesRiP_xeIAqNsYwvrNOwYcLc6npvKCynNm9cBIssYvGRYOkmsoo0qYR9hiP5lZiH8qqOIXGJWj_FnQo_0k3U_2diJGhGhGlcmTdTxacsMU7ixhdybuBZKXOXYpOzHwlf40MKgriKWD1vdYrqdvKPpX62heB0M1V3BaDpJCMqiYOVyu8PYYcbLK2mD4XUS5n4T4UNom_mVtcpnZehFIR-6DhT2xUeeyS85OgDuifphOiBUzjNBDXIIsVhZp23yzFzwBMnqdSrHOXZaA8bVStqVJ5Cysvdap0H70bO-4ToCAr0uQVD0VuUtvIE2R7uheleGwJlQk3RAEwq4uf11lY0PrwaiLY-S_u8RKGSIiECorx_cpuxbedMEqhY0YD71QA9oSqXDdUBm4q-d=w299-h398-no)

With a few bends and a bit of rattle can paint.

![[Image: RqJFrVtt4zvGpEzW3ZGVF50R_5lNfJwgqgwl-iN2...7-h1276-no]](https://lh3.googleusercontent.com/RqJFrVtt4zvGpEzW3ZGVF50R_5lNfJwgqgwl-iN2NKxCqLdM7-UNOR95eCRet0kMtjIe24aJeKRnhcPryboAhsZJIlqKOW5aoiuuru3rWq7YTkmdKvbpQEFRe3yOchdoUiD0QgFJSAPy4p0SX9cGdreKwr-o3pagn48WMucLGZql47lXgfCWcIJVzO4j33gfKOWyaTnSUTpSzYDxPhwCk1cKn9tS-TK7obgSa14_nTZuz2jy_vXDmn_Kuz1v_kA21Ttrsqjl3sl3ikhVRyM1L77NO7fyvZlNAr1RNXtqqVJatTIjiZvbMxhWL9uT9VDJ5W8NibypUA-bpYRI07SlnBQ8S0jH3rgZQvmpNFbm2wnTjw-8FqNuxWwUtRMD2A1YDchPlSM4LF6nFY24TRUASGXROShbMkEZuP1Lgpwwz4-cfFH043h5_-O_co673K4f9TWmdK9SUDWXXMSRk_GCEi-N9Oilyim4MpObAqBnn7quapPxEET4E2I5zBeILZHFxx8RibUzyZPZlELuk6C9RV6P9oIuGKYC3RbRvOjnazu6rcn0KYyNBkXAcfPrwUkuonKUccGnNnZGaOvOzgnT8B2n0gZry-wxt1ueNOo6VwFDYkRMf2Of=w957-h1276-no)

Free advice is worth exactly what you payed for it.

Greg

Posts: 535

Threads: 39

Joined: Jan 2013

Location: Kelowna, BC, Canada

Pete, if I had to guess, I'd say that was a Victoria or Elliott mill. Very capable machine.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

(05-31-2017, 10:37 PM)Hawkeye Wrote: Pete, if I had to guess, I'd say that was a Victoria or Elliott mill. Very capable machine.

How right you are Mike, it's a Victoria U2, marketed in the US as Elliott if my understanding is correct. The astute observer may have noticed that I did not strip, clean and paint it back in January as I had boldly stated my intent. Maybe one day.

(05-31-2017, 07:32 PM)f350ca Wrote: B een too busy in the cabinet shop Vinny. Still haven't got it powered up. But drop over anyway Pete, if you decide to come Im sure I can get it going before you get here.

Yours is a part of the world I'd dearly love to see, Greg. Again, maybe one day.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

|

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)