Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Thanks DA,

That is the correct manual.

I'll have another read, the thing that confuses me is I have two wires from the start button, and two wires from the stop button. So do I put one wire from the start to S1 and one wire from the stop to S2 and then common the remaining two wires to GND?

DaveH

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

Dave, is the "start" button a "normally open" switch and the "stop button" a "normally closed" switch?

Also, NEVER have any switches or circuit breaking device between the VFD (inverter) and the motor.

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

05-30-2014, 12:30 PM

(This post was last modified: 05-30-2014, 12:39 PM by stevec.)

Today I decided to cut the stump of one of the oaks I took down on our front lawn.

Here it is ready to test the log lifter on my splitter.

I think I'll try and rotate it to a better position for the first split.

This looks a bit better.

That is better, still had to help complete the separation with a few whacks of the axe.

Here's the second split, things are getting a bit more workable now.

a little more work and we have wheel barrow overload with stackable (sorta) firewood.

More work than I counted on, I`ll leave the second stump til tomorrow.

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

05-30-2014, 12:43 PM

(This post was last modified: 05-30-2014, 12:57 PM by DaveH.)

Steve,

The Stop and Start push buttons I have can be either normally open or normally closed.

I understand nothing is to go in between the inverter and the motor.

I don't have to put in a start and stop push button at this time for the log splitter. However in the future when I change the lathe motor I will want a stop, start button, reversing switch and speed control and read out.

DaveH

PS I didn't buy the stop and start buttons for this particular job, I've had them laying about for years.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Nicely done Steve.

Your control valve is it a detent type?

DaveH

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

(05-30-2014, 06:47 AM)stevec Wrote: I hear ya Dave, I too am trying to "translate" the chinglish manual that came with my VFD.

Steve,

What are you trying to do with your VFD? I'll try to help out.

Ed

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

(05-30-2014, 01:19 PM)EdK Wrote: What are you trying to do with your VFD? I'll try to help out.

Ed

Hi Ed,

Just trying to understand how to wire in a stop and start button into the VFD, and where to connect all the wires to.

One would think in a manual of 100 pages there would be:

1) How to wire in a STOP button

2) How to wire in a START button.

3) How the wire in a REVERSING switch.

They are there just not clear to me

DaveH

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

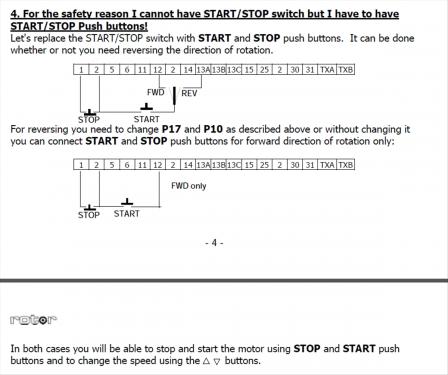

These instruction are not for my inverter, nevertheless instructions like this I can nearly understand. I say nearly because are the start and stop buttons both normally open?

DaveH

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

(05-30-2014, 01:45 PM)DaveH Wrote: Hi Ed,

Just trying to understand how to wire in a stop and start button into the VFD, and where to connect all the wires to.

One would think in a manual of 100 pages there would be:

1) How to wire in a STOP button

2) How to wire in a START button.

3) How the wire in a REVERSING switch.

They are there just not clear to me

DaveH

Dave,

I can help you. I didn't respond because you said you weren't going to wire those in on the log splitter but on your lathe later on. I'll draw something up and post it.

Ed

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

The following 1 user Likes EdK's post:

Highpower (06-06-2014)

(05-30-2014, 02:11 PM)DaveH Wrote: These instruction are not for my inverter, nevertheless instructions like this I can nearly understand. I say nearly because are the start and stop buttons both normally open?

DaveH

Dave,

You always want the stop button to be a normally closed button. That way if a wire breaks in the stop button circuitry it'll look like you pressed the stop button which is what you want for safety purposes.

Ed