Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

11-11-2012, 08:12 PM

(This post was last modified: 11-12-2012, 05:40 AM by Mayhem.)

I was given an 1045 mild steel automotive hub that was destined for the scrap bin as it had been machined incorrectly, from which I plan to make my spindle nose clone. I flame cut most of the flange off and then cleaned it up as best as possible. Of course, this results in a less than concentric section that still needs machining.

I used a Tungaloy CCMT 9T304-24 T725X insert for this, as these are described as being for "Low to medium speed turning...effective in roughing, heavy and interrupted cutting where the cutting load varies".

Once the remainder of the flange was turned down to the point that I was cutting continuously I noticed that I wasn't making chips. Given that I was at the top speed for my lathe, I increased the depth of cut from 1mm (.040") to 1.5mm (.060") as the DOC for this chipbreaker is in the .050" to .140" range. However, the increased DOC actually started to slow my spindle. So, I backed the DOC off and decided to increase my feed rate (manually). This also worked but again started to slow the spindle when I fed it fast enough to break the chips.

Is there anything else I can do here or do I just reside myself to the fact that this is the best I can get from these? I guess that I should have tried a DOC of .050" and a faster feed but I didn't think of that at the time.

I switched to an Iscar CCMT 9T304-SM IC907 insert which did a nice job of braking the chips at a 1mm DOC and even down to .5mm (.020), which is the minimum recommended DOC. I'm starting to document insert grade/chipbreaker performance in known materials, so your thoughts and comments are always welcome.

Edited to fix up format issues and missing text (in blue). I did a cut and paste on my phone and must have screwed up!

Hunting American dentists since 2015.

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

11-11-2012, 10:12 PM

(This post was last modified: 11-12-2012, 07:03 AM by PixMan.)

I didn't find much detail on that Tungaloy grade, though the newer AH725 is probably it's improved version of a fairly tough PVD TiAlN-coated grade. I can't imagine any CCMT32.51 (CCMT 09T304 in ISO language) to be capable of a depth of cut that deep, no matter how tough it may be. The chipbreaker "24" appears to be a nearly flat, short-length to the ramp-up roughing geometry.

When you say that when you got the the continuous cut and "noticed that I wasn't making any chips.", just what WAS it making? Long stringy chips, perhaps? The reason it slowed you machine is probably that the insert top form geometry (chipbreaker) is so neutral/flat that it generated more force than your machine has torque to overcome. In a case like that, switching to an insert with a more upsharp geometry would cut with less force, and that's what the Iscar SM chipbrealer did for you rather than the grade. The IC907 is also a PVD (Physical Vapor Deposition) TiAlN coated carbide, but a much harder substrate of submicron-grain carbide for higher heat and wear resistance. It (IC907) is typically used in austenitic stainless steels and nickel-based superalloys.

With the Tunagloy 24 chipbreaker, if you were indeed starting to get long chips, then increasing feed rate is usually the remedy. Sometimes that won't work though. If you are already overriding the chipbreaker than higher feed just makes it worse.

As always, match the coating and grade to the material, match the chipbreaker to the depth of cut and feed rate for a given material.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

11-12-2012, 05:24 AM

(This post was last modified: 11-12-2012, 05:43 AM by Mayhem.)

Thanks Ken,

This is what I found on Carbide Depot when I first got these inserts:

Manufacturer: TOSHIBA TUNGALOY

Chipbreaker Name: 24

Operation: TURNING/BORING

Application Range: LIGHT CUTTING

Description: 'For medium cutting - positive inserts. General purpose, all-round groove chipbreaker used for a wide range of applications. Performs well in medium to rough boring operations.'

Grade name: T725X

Insert material: CARBIDE - CVD COATED

ISO range: P20-40

ANSI range: C5-C6

Coating: 12-layer CVD + X-coating

Description: 'Low to medium speed turning of various steels. Very effective in roughing, heavy and interrupted cutting where the cutting load much varies. Improved toughness and reliability due to the tough and fine-grained 12 layer coatings and toughened substrate.'

Here is the graph that I located (cannot remember where though):

clip_image001.jpg

clip_image001.jpg (Size: 34.39 KB / Downloads: 133)

Perhaps I have screwed up reading the graph?

It was based upon this info that I selected this insert, especially since it was described as being suitable for interrupted cuts. However, I'm guessing the IC907 would also hold up pretty well in those conditions. However, of the two, the T725X was the grade for steel.

I just looked in the 2011-2012 catalog and they show the chipbreaker but not the grade, although the grade you referenced is there. Here is the page:

Tungaloy General Catalog 2011 135.pdf

Tungaloy General Catalog 2011 135.pdf (Size: 111.78 KB / Downloads: 2)

Sorry for the lack of description of what was happening when it wasn't cutting chips. It was, as you described, producing long curly swarf. In fact, it was the interruption in the cut that breaking the chips. The finish was fine regardless of how it broke the chips. I also noticed that in posting the original post on my phone, I missed out the fact that the increased DOC also slowed down the spindle. I don't think this changes anything but I thought I would throw that out here just in case (I edited the OP to include that).

I can set the spindle speed and DOC but at the moment the feed is variable on how fast I crank the hand wheel. I thought I was making the right adjustments. This is a good learning process and the results are in my notebook for future reference.

Thanks again for your comments, they are (as always) very helpful.

Hunting American dentists since 2015.

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

That chart/graph you posted certainly confirms the recommended depth of cut to be anout .045 to .150. Even then, the .150 is almost half the width of the insert and that seems excessive for a small screw-down insert. Possibly that chart was more for a big CNMG432 insert? That's kind of the default for a lot of stuff. The catalog page you linked to does show a profile of the 24 chipbreaker, and different D.O.C. values. Note the .008"/0,2mm land, and the D.O.C. of about .5mm up to about 3mm. Also note how the "backside" of the D.O.C. & feed rate combo chops off? If you have max D.O.C., the max feed rate can't be used and vice-versa. That's probably because the extremes would be too much force on the small I.C. size inserts.

It's interesting that the T725X grade is CVD (Chemical Vapor Deposition) coated. I like that better for steels as it's thicker. Because it's done at higher temperatures than PVD and is thicker, it needs a heavier edge hone to prevent build-up. A sharp edge would degrade in the higher temps anyhow. I'm surprised it's not closer to the new grade. It does look perfect for steels.

While the IC907 Iscar grade can be used in smooth turning of steels, that's not the best application for it.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

I'll try a shallower DOC and increase the feed, as you are probably correct on the graph being non-specific for that size insert. For all I know, it could be for a totally different insert, as I did find it when I first picked up those inserts and I knew even less then than I do now! I hope I didn't do something stupid and copy it from the milling section  So really, I need to make sure that I find the f-ap data specific to the particular insert I'm using/looking at on eBay. I'll keep in mind to only try and max out one variable at a time and that is good info to have.

However, I'm not sure I completely grasp the coating/geometry relationship there. Are you saying that I'm unlikely to find an upsharp geometry (which would reduce the cutting force) in a CVD coated steel grade?

Come to think about it, I don't think the IC907 produced as nice a finish as the T725X but I'l have to wait until I'm back in the shop to confirm that.

I think I'm starting to get a better understanding.

Hunting American dentists since 2015.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

I thought I'd post a few pics in case anyone is following along at home

First is the issue I was having in breaking the chips. You can see the blue stringy mess in the gap and draped over the leadscrew. These come of a straw colour and turn blue, as they transfer the heat. I actually took this after I had turned down the 1045 hub and a mystery metal drill coupler (that I had to anneal) is chucked up. I was turning this to be a press fit inside the hub, as I didn't have a lot of length to play with.

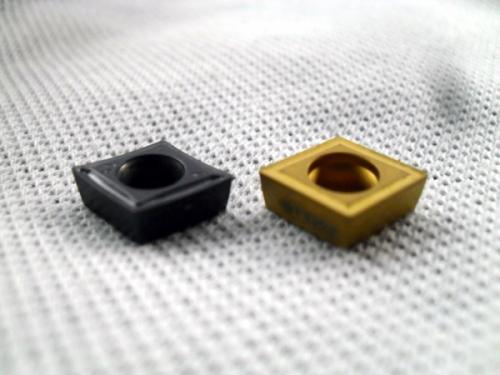

Here is the Tungaloy CCMT 9T304-24 T725X (CCMT 32.51 in ANSI) insert.

Here is the Iscar CCMT 9T304-SM IC907 (CCMT 32.51) insert. What is great about this insert, is that the box actually has the feed and DOC data on the box, as well as the Grade (M) and Range (05-20). The Tungaloy inserts don't have this on the box, neither do any of the Walter or Valenite turning inserts. I'd have to check the milling ones I have.

Finally a side-by-side comparison in which you can basically see the difference in the chipbreaker (top form geometry).

One thing I do when buying inserts is that I avoid the cheap non-name ones that have a generic description like "ideal for general machining of steel". I may pay a little more but with a name brand I can be fairly sure that I can find out the what the grade and chipbreaker are most suited to and whether that meets my needs.

If you take your time and do your research you can get some very good deals on inserts from eBay. Especially if the grade has been superseded. But hey, we are not doing production work, so the inserts that were top line last month will still do us fine.

Hunting American dentists since 2015.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

11-13-2012, 09:48 AM

(This post was last modified: 11-13-2012, 09:50 AM by DaveH.)

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

What has your experience been with those Dave?

Hunting American dentists since 2015.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

I have found them to be great, I use them for aluminium, brass, copper, bronze, mild steel in fact everything  and the occasional 303 stainless. Cut some nylon once.

I have to say I don't take large cuts (I've always been this way) the max I would take is .040" and that's pushing it. I haven't broken one yet, and they last very well.

Sometimes I will use a bit of cutting fluid sometimes I don't, I have no set rule.

Overall for the home shop environment I think they are an excellent insert to use.

I used the same one through out to make the ER25 chuck, the adapter and the aluminium taper gauge, so they do last quite well.

It will be interesting to hear how you feel they measure up.

DaveH

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

If shopping,the Iscar IC907 has now been superceded by IC908. Very similar grade & coating, same chipbreakers available.

Those are a sub-micron grain size carbide, TiAlN coated. There are at least two other brands that have grades that are just aboutidentical, only the chipbreaker changes. Keep your eyes open for Valenite's 9605 and Kennametal's 5010 grades. Be aware that although they work OK in steels for limited use, they will fail in the soft stuff after a time. That said, those grades will do some amazing things in hardened steels up to about 55Rc.

|

So really, I need to make sure that I find the f-ap data specific to the particular insert I'm using/looking at on eBay. I'll keep in mind to only try and max out one variable at a time and that is good info to have.

So really, I need to make sure that I find the f-ap data specific to the particular insert I'm using/looking at on eBay. I'll keep in mind to only try and max out one variable at a time and that is good info to have.

and the occasional 303 stainless. Cut some nylon once.

and the occasional 303 stainless. Cut some nylon once.