I need a couple of flat wrenches, similar to those supplied with routers. ( http://www.amazon.com/Porter-Cable-42596...B0009H5LQM)

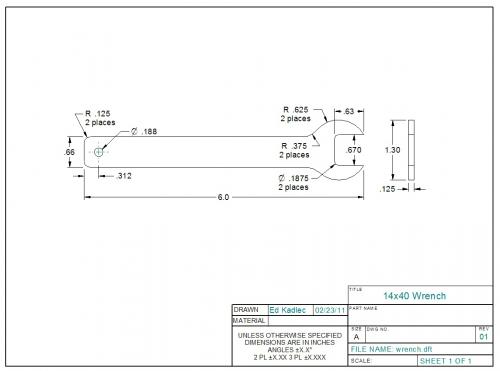

I want 2" and 2-1/4". I don't have a torch, nor would I know how to use one... I guess I could machine them out of flat stock, but I'm not sure what to use. Would 3/16 CRS be adequate? Thicker aluminum? It seems to me that the router bit wrenches are hardened (at least, they don't like being drilled through.)

I need them for tightening and loosening a collet chuck, so it's not like I'm taking apart a bulldozer.

Suggestions?

Posts: 8,890

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Mike,

3/16" CRS should be fine as long as you have enough meat at the tines of the wrench (not sure if "tines" is the correct terminology). I made some smaller open end wrenches out of 1/8" CRS for tightening the backlash adjusting nuts for the lathe cross slide and they work fine.

Ed

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

I go into town I can check and see if Steve's Wholesale has them in that size, I know they carry a wrench in the style your wanting. si does Wholesale tools although they aren't very cheap

http://www.wttool.com/index/page/categor..._params%3D

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

Thanks, both of you. Ed, how did you do the big outside radius? Did you mill it square, and grind/file to shape?

Dallen, that's exactly what I want, but, needless to say, way more than I want to spend! Thanks for the link, though. If you think about it when you're in town, check the other place, please.

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

Posts: 8,890

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

(09-26-2012, 12:19 PM)Wawoodman Wrote: ...Ed, how did you do the big outside radius? Did you mill it square, and grind/file to shape?

Mike,

I milled most of the large radius by turning the vise a bit at a time to get the majority of the steel removed. Then I used Bob's (krv3000) method of filing it to shape. Since it wasn't a critical dimension, I wasn't too fussy about getting the radius exact.

Ed

dallen,

I have a rotary table, but I've never used it. I guess it's time to learn!

Ed,

Could you post a link to Bob's post?

Posts: 8,890

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

(09-26-2012, 03:26 PM)Wawoodman Wrote: Ed,

Could you post a link to Bob's post?

Sorry Mike. Bob does not have a mill so he does a lot of his shaping with a file and does a fantastic job. I was just referring to Bob's expertise on using a file and not suggesting any particular post of his to refer to.

Ed

Posts: 3,799

Threads: 184

Joined: Jun 2012

Location: Farmington Hills, Michigan

Mike,

If you are going to the trouble of making a tool, go the extra mile and harden it. It'll hold up better for its intended use and it won't get all beat up from getting knocked around. You can either make it out of O1 to begin with and then harden and temper it with a torch, or you can save some money and make it out of mild steel and case harden it afterward. Either way you'll end up with a much nicer tool.

Tom

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

09-27-2012, 07:10 AM

(This post was last modified: 09-27-2012, 07:11 AM by stevec.)

This is probably machining heresy and/or suicidal but I have shaped rounded ends on rectangular parts by drilling a hole in the centre of the end for a pivot pin which is held in the mill vise. Feed the vise toward the end mill and turn the part with your other hand. Take small cuts and DO NOT CLIMB CUT! Start at the apex of the corner you want to round off so as not to cut too deep as you're arcing the part into the side of the endmill. once the radius is done to your liking back off and flip the part over for the other side, If the part isn't long enough to be safely held by hand , hold it with vise grip pliers the added landth gives mechanical advantage and better control.

A better pivot pin would be one threaded for a lock nut to keep the part from lifting.

For large radii I rough cut excess metal off on the bandsaw to reduce milling time.

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

|

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)