Posts: 340

Threads: 24

Joined: Aug 2014

Location: Seattle, WA

The following 1 user Likes wawoodman's post:

f350ca (02-24-2017)

Years ago, my lumber supplier used to send me mahogany 18-24 inches wide, any time I asked. Those days are gone, I'm afraid...

Mike

SB 10K (1976) Rockwell vertical mill (1967) Rockwell 17" drill press (1946) Me (1949)

Posts: 432

Threads: 27

Joined: Feb 2016

Location: Woodstock:GA

The following 3 users Like pepi's post:

f350ca (02-25-2017), arvidj (02-25-2017), EdK (02-25-2017)

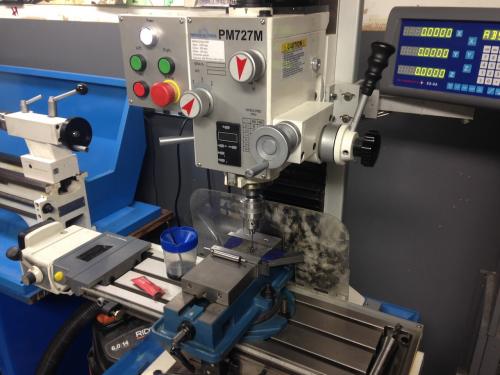

OK I'm doing some metal, a bracket that bolts to the side of a front loader bucket. It will mount a hydraulic driven chainsaw, the mount supplied is the old one size fits all type ....not so great.

Certainly not a do-all, I call it a do-some, have it for 10 years, with a few mods it cuts clean and accurate. Next change i'm making will upgrade with a Lenox blade.

^^^^^

Cutting, RH or lower blade guide runs into the side of the material.

Cutting temporary stopped, on the fly mod made seen below, parts done.

V V

Small locator holes drilled, using edge finder makes that easy.

More holes, 3 two thur and one for a blind nut and bolt

Too the welding table, first assembly and welding

more later

Greg

Magazines have issues, everything else has problems

Posts: 63

Threads: 10

Joined: Jun 2015

Location: Medford, Or

The following 1 user Likes Thumb's post:

TomG (02-26-2017)

I just put up an 8' LED light in my shop over the mill and what a difference. I have two other 8' florescent lights in there also and the LED is brighter than both of them put together. Only thing is that the $90 price tag on the LED scares me and I wonder how long it will last.

Posts: 432

Threads: 27

Joined: Feb 2016

Location: Woodstock:GA

The following 4 users Like pepi's post:

TomG (02-26-2017), f350ca (02-26-2017), EdK (02-26-2017), aRM (07-22-2017)

The set of holes that looked like they were pilot holes were not. Actually the were for this silly drawing, and the reason? Created a template to tape on the side of the bucket, center punch and drill.

Then flipped the mount and finished the welding.

Using the edge finder locating the hole center, drilled them to .5 for the fasteners, I used tap magic for the drilling to see what the results would be. It punched some really clean holes, will try that some more.

painted.. done picked up

Want to mention that this edge finder is very nice, dual purpose. It chucks to the center section. Second the hole finder is used statically, can be used with a drill press. Get the hole drilled where the center pinch left its mark...

That's all folks,

Greg

Magazines have issues, everything else has problems

Posts: 799

Threads: 52

Joined: Mar 2012

Location: Rochester, NY

Thumb, you can get 4' LED bulbs (to fit standard fixtures) from Greenlightdepot.com Bulbs for ballasts, or ones that bypass it. Less than $7 a bulb for the ones I got (5000k color, bypass) and shipping is quite reasonable ($11 for 10 bulbs), too.

I won't ever buy another CFL or 4' fluorescent bulb ever again. LED is soooo much better all around.

Full of ideas, but slow to produce parts

Posts: 2,629

Threads: 101

Joined: Dec 2014

Location: Michigan

Thanks for the tip! I just ordered 5 to replace some around here.

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

The following 7 users Like f350ca's post:

Vinny (02-26-2017), TomG (02-26-2017), DaveH (02-26-2017), Mayhem (02-27-2017), rleete (02-27-2017), EdK (02-27-2017), aRM (07-22-2017)

Have the cases pretty much done, now to make 32 drawers. Bought the felt for the drawer bottoms today, 4 yards, looks like a lot of felt.

![[Image: cK6q1QizYhOaVtYJNj3QPcoZgWaVQ0n7A444ziAM...7-h1276-no]](https://lh3.googleusercontent.com/cK6q1QizYhOaVtYJNj3QPcoZgWaVQ0n7A444ziAMgl2rM6R8tnCjtyZNSMZVB60MwDPuC0dmuw773Bfs1xmK6KXsueReNjJAdoI0XWMsPNgsf7M9_TDh9qpXo4YGuittLPRNPWxazc_N-AIIS2tTEfG-J4HQdkOAkuHvEok-mKzlvn6YCqm7cDj0UlhkgKfZKPZAju1g5dJxDagl940CHTS3SvErAH-cpB7BZ5Rkvkc5X1mMgiZUjtuQ6QPfCTT5ahTpZS92-5BMURU1jsJqKlhEbXa-sFR3CvA95j7FcpNKj7TP3Myg_GpzihaExNoLF7LiCTm-HShCIcdel-THfFwWWIj4DDTJDy35C5sCPBRwFQ1ZA9fpsH-V2xcMnzN_clc7KHagQZtjpO4lZfhMQnqmYmPI0QmNK8REdJ5PO5AvodB4I5bicIgr7ZHXRDnG3Z5pxq2g7SKMUQG9zPyJxpAVnNREeSNgyc-hIF63Juy5WB7iNGIUjpKHEYJTGDyKB8SNmHr0W7c3uo-ibInpaV6yiNVE3BY5OYMphOnbWBGMyE73DI_iWTGKi_905bp5yjYKoaAICqH8oxUI0LP7pjZ2PM0mgytUCYF6bt0zkg1dxkmT9gF4=w957-h1276-no)

Free advice is worth exactly what you payed for it.

Greg

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

The following 4 users Like Mayhem's post:

f350ca (03-05-2017), EdK (03-06-2017), TomG (03-10-2017), aRM (07-22-2017)

Two jobs done this weekend - both for mates.

Job one - repair for the wire feed on a mig welder. Poor design, as the roller is unsupported at the end where the tensioning roller pushes on the wire. The result is that the shaft tips inside the needle roller bearing causing wear to the shaft. The net result is that you can no longer get sufficient pressure on the wire to feed. You can see the worn section quite clearly.

I couldn't make a new shaft, for obvious reasons but I could cut out the worn section and replace it. So that is what I did. No access to a 4-jaw chuck, so I indicated the part in the mill and drilled a 7mm hole through the centre.

Next the ends that I need to keep were parted off in the lathe.

To ensure concentricity, the new section was turned in one process.

Finally, it was welded together and the ends cleaned up.

Job two - modify the sling mount on an old side by side 12ga hammer shotgun. This is the one that is screwed into the web between the two barrels. I had already milled off the old mount before I thought to take pictures. So here is the bracket alongside the new mount.

I made up a quick jig to hold the parts in the correct orientation for welding and milling.

The finished product.

Hunting American dentists since 2015.

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

The following 1 user Likes Pete O's post:

TomG (03-10-2017)

I had a bit of time between sleeping in and going to my night shift, made a start on machining a chunk of the forklift tine. I was thinking I might have to anneal it but it cut ok in the bandsaw so I put this lump in the shaper and put a surface on one side.

The piece is 50x130x300mm (around 2"x5"x12") and I was going to surface one of the wide faces but I don't have a vice that will open that wide. Still searching for a shaper vice.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

(03-06-2017, 10:30 PM)Pete O Wrote: ...I was going to surface one of the wide faces but I don't have a vice that will open that wide...

Could you get creative with a clamp set? You would have to do it in to stages though.

Hunting American dentists since 2015.

|