Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

The following 1 user Likes PixMan's post:

EdK (04-13-2014)

Finished up the screw for Darren by milling the 6mm wide x 20.25mm long keyway and putting in the 5mm hole called for on his print.

The keyway was a good exercise for me with the conversational Prototrak control on my Alliant milling machine. Because I don't have a 6mm end mill, I used a 4-flute solid carbide 13/64" (0,2031") end mill I had kicking around and used cutter diameter compensation to make it cut 6mm (.2362") wide. It took a couple of passes to get right, largely due to not having a reliable method of gauging the width. In the end I used the 6mm shank of a 1/8" solid carbide drill I have as my gauge, making that a very snug fit. I presume that a 6mm key will be on the small size, so it should fit with a tap in.

![[Image: IMG_20140412_164821124_zpsxbj3myf3.jpg]](http://img.photobucket.com/albums/v466/kenm10759/Dads%20shop/IMG_20140412_164821124_zpsxbj3myf3.jpg)

Posts: 535

Threads: 39

Joined: Jan 2013

Location: Kelowna, BC, Canada

The following 3 users Like Hawkeye's post:

stevec (04-13-2014), PixMan (04-13-2014), EdK (04-13-2014)

04-12-2014, 11:08 PM

(This post was last modified: 04-12-2014, 11:17 PM by Hawkeye.)

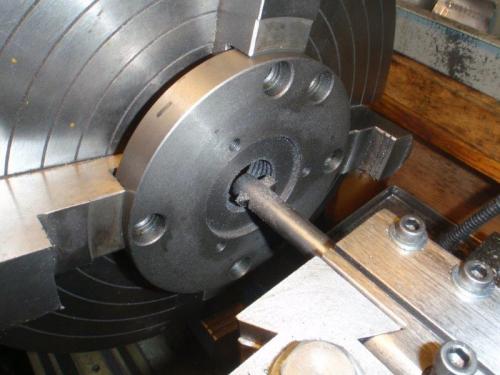

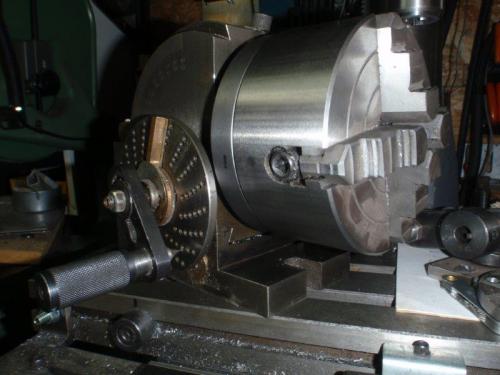

The chuck that came on my dividing head was a nice 6 1/4" 3-jaw. Unfortunately, the size of it prevents a bolt from being used in the front slot when mounting the DH on the mill table. I have a 5" 4-jaw that has a backing plate with a hole just a bit smaller than the minor diameter needed for the M30 x 3 spindle thread. Easy to use a carbide boring bar to take it to the right size.

When it came time to cut the internal thread, I needed to make a split sleeve to mount my 1/2" boring bar with the threading bit. Cut a piece of 3/4" CRS, drill and ream to 1/2", slit on the horizontal mill - done deal.

Pretty standard threading job, after I had swapped out some gears to cut a metric thread.

When the thread was 'visually' complete, I tried it out without removing the plate from the 4-jaw on the lathe. Since a 10 1/2" is a bit too heavy to spin off and screw onto a dividing head, I had to set the DH up to the hole on the lathe and crank it into the hole. It takes quite a while to crank in a 40:1 DH. I'm just glad it was already the right size. Nice snug fit.

After the fit was proven, I cut a 1/4" deep section at major diameter. The backing plate tightens up very nicely on the DH spindle.

The end result is that I can attach the DH to the mill table much more easily.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

Thanks Ken - I really appreciate your time and efforts in making this for me. I'll get you the height for the 5mm pin shortly.

Hunting American dentists since 2015.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

Mike - nice work on the backing plate.

Hunting American dentists since 2015.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

That looks a job well done Mike

DaveH

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

Mike, I envy you that tilting dividing head! Nice work indeed, getting it fitted with a good chuck.

I'm not actively looking for one of those, but I will eventually come across one and it would be on my "must have" list.

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

nice job on the backing plate, at 10.5 inches it would make my little 4 inch DH look like a toy.

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

Posts: 535

Threads: 39

Joined: Jan 2013

Location: Kelowna, BC, Canada

The 10 1/2" is the 4-jaw on the lathe. I was using it to hold the 5" backing plate for machining.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

The following 2 users Like PixMan's post:

Mayhem (04-14-2014), EdK (04-14-2014)

Got some shop time today because it started off raining. With most of Darren's elevation screw & nut project done, I had to take some time to work on the motorcycle parts for Neil (expat.)

Two castellated nuts for axles I'd previously made. I got one completely done, the other still needs the slots put into it.

The turned, drilled, tapped and hex milled blanks:

![[Image: IMG_20140413_165629184_zpsrm8txd2q.jpg]](http://img.photobucket.com/albums/v466/kenm10759/Dads%20shop/IMG_20140413_165629184_zpsrm8txd2q.jpg)

The finished one:

![[Image: IMG_2252-r_zpse5a0fdde.jpg]](http://img.photobucket.com/albums/v466/kenm10759/Dads%20shop/IMG_2252-r_zpse5a0fdde.jpg)

Posts: 3,798

Threads: 184

Joined: Jun 2012

Location: Farmington Hills, Michigan

Hey Ken, are you going to make the cotter pins for them as well?

Nice job!

Tom

|

![[Image: IMG_20140412_164821124_zpsxbj3myf3.jpg]](http://img.photobucket.com/albums/v466/kenm10759/Dads%20shop/IMG_20140412_164821124_zpsxbj3myf3.jpg)

![[Image: IMG_20140412_164821124_zpsxbj3myf3.jpg]](http://img.photobucket.com/albums/v466/kenm10759/Dads%20shop/IMG_20140412_164821124_zpsxbj3myf3.jpg)

![[Image: IMG_20140413_165629184_zpsrm8txd2q.jpg]](http://img.photobucket.com/albums/v466/kenm10759/Dads%20shop/IMG_20140413_165629184_zpsrm8txd2q.jpg)

![[Image: IMG_2252-r_zpse5a0fdde.jpg]](http://img.photobucket.com/albums/v466/kenm10759/Dads%20shop/IMG_2252-r_zpse5a0fdde.jpg)

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)