Posts: 8,891

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

The following 1 user Likes EdK's post:

Chad (12-12-2024)

(02-19-2012, 05:34 AM)RobWilson Wrote: Hi Ed

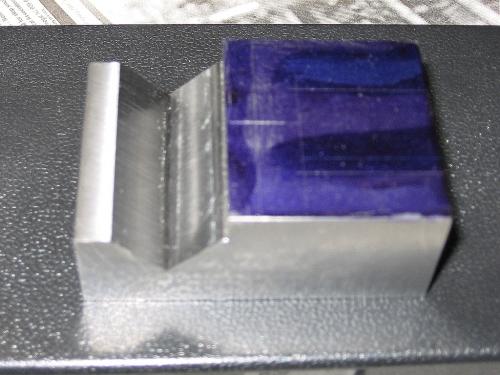

Now thats a very well machined addition to your lathe ,, I like how you have went the extra mile to round off the corners of the body , touches like that really add to the look of the finished part .

If you don't mined i think i will follow your lead and make one for my CUB lathe

Rob

Rob,

I'm flattered.

One condition though. You have to post it as a project. Always a catch, isn't there.

Ed

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

02-19-2012, 10:26 AM

(This post was last modified: 02-19-2012, 10:27 AM by PixMan.)

That certainly is one of the prettiest I've ever seen too. I don't know of any factory stops with that kind of attention to detail and finish.

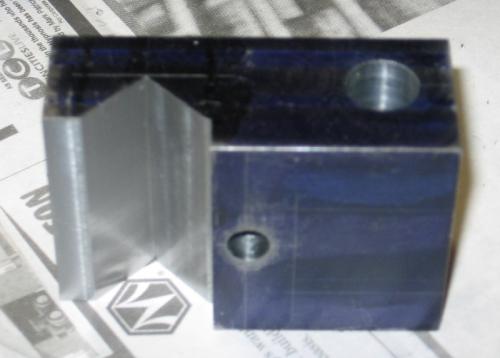

About the only thing I might have done differently in design would be that I would make the thread a 40 pitch and leave a straight, clean ring of the major diameter of the adjusting nut to allow inscribing .001" graduations. That would make it a micrometer carriage stop.

What pitch thread does it have now? Looks like it might be about a 20TPI. If that's the case the adjusting nut seems big enough that you could turn a short (1/8"?) wide diameter just below the depth of the grooves, make a press-fit aluminum ring and inscribe 50 graduations around it.

Just a thought.