Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Posts: 794

Threads: 52

Joined: Mar 2012

Location: Rochester, NY

My large (5 D cell) maglight had a very thin internal snap ring inside. I never did get it out to replace the bad switch. Just no way to get a grip on it.

Full of ideas, but slow to produce parts

Posts: 4,493

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

The following 3 users Like Highpower's post:

JScott (05-31-2023), EdK (05-31-2023), Vinny (05-31-2023)

(05-30-2023, 04:51 PM)rleete Wrote: My large (5 D cell) maglight had a very thin internal snap ring inside. I never did get it out to replace the bad switch. Just no way to get a grip on it.

This one has a thin spiral snap ring in it too although the internals

should be able to slide out the back of the tube without having to remove the snap ring. Even so I removed it anyway because it looks like I'm going to have to hammer out the internals. Corrosion has them locked solidly in the tube. The batteries didn't get stuck but the LED base and the switch assembly did. I'll try a little vinegar soak to see if I can loosen things up first. I would rather take the short route (out the front) rather than all the way through the back of the tube.

![[Image: ea363ec5.jpg]](https://www.wavesspring.com/uploads/ea363ec5.jpg)

Back in the 80's I used to carry a 7 D cell Maglite in the cab of my pickup. Made for a good baseball bat in a pinch as well.

Willie

Posts: 4,493

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

I shoved a wad of paper towel down into the tube and up against the back of the switch assembly. Got it good and wet with some white vinegar and let it sit for roughly 45 minutes. When I went to pull the paper towel out of the tube I noticed the top

1/3rd of the switch moved back slightly all on it's own.

Then I was able to push that piece out through the back of the tube with a pocket screwdriver using the push-button hole in the top of the flashlight body for access. After that was out there was plenty of room to push the rest of the switch out too. The base of the LED module was still stuck tight in the tube though. Had to break out the heat gun and warm up the tube to get some expansion going, then used a piece of 1" schedule 40 PVC pipe and a dead blow hammer to finally drive it out of the tube. Once it was out I could see that the inside of the tube is knurled where the LED base presses into it. So it's not meant to be a slip-fit.

Also it turns out the "switch" assembly is stacked together using 3 housing pieces and a printed circuit board. The actual "switch" is just a metal snap dome wafer that makes contact with pads on the opposite side of the PCB. I got all the pieces cleaned up and put back together and it lives again. That's $60 I

didn't have to spend again to replace it!

Willie

Posts: 2,629

Threads: 101

Joined: Dec 2014

Location: Michigan

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Posts: 4,493

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

The following 3 users Like Highpower's post:

Vinny (06-01-2023), EdK (06-01-2023), JScott (06-02-2023)

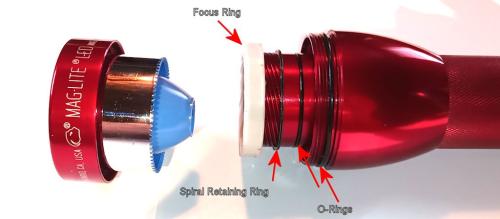

I failed to show the answer to my original question as to how the get the head off of one of these things. The "bowl" of the head is no longer threaded onto the flashlight tube. It just

floats over it on these LED models. You

must unscrew the front lens bezel ring from the bowl instead. That will give access to the rest of the parts. I fought to get it apart again just to take another picture to show the next poor guy that needs to do it.

Turn the plastic focus ring off of its splines, remove the outer spiral ring and the o-ring behind it, and then the bowl just slides right off the front..

Willie

![[Image: ea363ec5.jpg]](https://www.wavesspring.com/uploads/ea363ec5.jpg)