Embarking on a new project. This could take a while.

Bought a set of plans for a model of a 1910 Holt tractor engine, they were the predecessor to Caterpillar.

Its hopefully going to be a 4 cylinder overhead valve engine.

A lot of small parts for my big fingers and machines. lol

1 inch bore and 1 5/8th stroke. It has wet sleeves and individual jugs on a two piece block.

The plans call for 32 DP gears, that size cutters don't seam to be available from our Chinese cousins and a set of domestic ones is pretty pricey. Saw an article where a chap made a none spiralled broach. The center cutter cuts the tooth and the adjacent ones top and form the next gear teeth over. Made a cutter and it seams to work.

The camshaft gear and a depthing tool I made

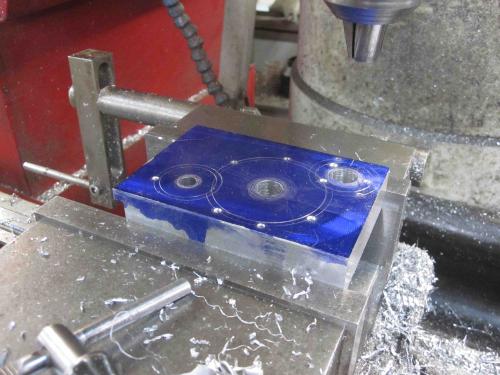

Today I started the front gear case. Some scrap aluminum from an aircraft plant, sure machines nice.

Bought a set of plans for a model of a 1910 Holt tractor engine, they were the predecessor to Caterpillar.

Its hopefully going to be a 4 cylinder overhead valve engine.

A lot of small parts for my big fingers and machines. lol

1 inch bore and 1 5/8th stroke. It has wet sleeves and individual jugs on a two piece block.

The plans call for 32 DP gears, that size cutters don't seam to be available from our Chinese cousins and a set of domestic ones is pretty pricey. Saw an article where a chap made a none spiralled broach. The center cutter cuts the tooth and the adjacent ones top and form the next gear teeth over. Made a cutter and it seams to work.

The camshaft gear and a depthing tool I made

Today I started the front gear case. Some scrap aluminum from an aircraft plant, sure machines nice.

Free advice is worth exactly what you payed for it.

Greg

Greg

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)