Coming back to this thread on induction heaters I had a project in mind but can't decide if I should attempt it or not.

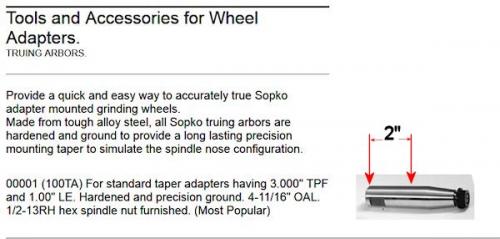

I bought one of these hardened and ground truing arbors with the intention of turning down a portion of the 1" shank to 3/4" so that I can use it in my mill. My first mistake was

assuming this was a through hardened piece of material. It is not. AFTER I bought it, I find out it's is a piece of 8620 that has been case hardened .020/.030 deep to 52/56 Rc. 30 Rc. Below case.

After my last encounter with hard turning (linear shafting for my shop microscope stand) and eating up 4 or 5 normal carbide inserts to get it done, I pried my wallet open and ordered one single CBN grooving/turning insert from MSC to the tune of $120. After several weeks of waiting it

should arrive next week. I'll use this to remove the first 2 inches of case hardening and get down to the chewy nougat center. Once I get it turned down to 3/4" diameter I'll be left with a relatively soft shank. So... I have this induction heater and an original can of KASENIT.

Left brain and right brain are fighting it out. Attempt to re- case harden

half of the shaft for wear protection and HOPE it doesn't warp the other half - or just leave it the heck alone and take my chances that way?

I could have made one from scratch ( I still have some 4140) but I don't own a surface grinder. I thought (

assumed) I was buying a

through hardened and ground "tough alloy steel" arbor that I could simply turn down but Noooooooooo....

In hindsight I wish I would have contacted SOPKO and asked about the material

before I bought the arbor. I do have to say they did an EXCELLENT job responding to my inquiry (a few hours) and gave me the detailed info above without hesitation. Superb customer service.