01-24-2019, 01:04 AM

The lathe purchased 2017 at a reasonable price came with a broken bull gear tooth and a seized threaded on spindle back plate on which was mounted a three jaw chuck, the reason for said seizure as can be seen here, although the absence of oil and/or grease on the threads was confirmed later:

and here

and here

Being a relative newbie, although i had some experience back around late 1960's at Repco with brake lathes, i took up a course in u-tubing and lo and behold to my amazement i retained enough knowledge offered by the many savants to tread very carefully through this metal minefield. Spindles are precious.

Long story short, my first machining job made sense whilst the spindle's 8TPI 2.25" thread was well and truly seized the back plate. The project was to make a 1" draw bar (the largest material on hand) in an attempt to wrestle the back plate off the spindle. As it turned out even with one metre (oops one meter - for our American friends) breaker bar on one end and a three meter (i'm learning) piece of 2" dia. thick walled galvanized work pipe on the other end there was no movement no matter what was done. Including using a 1" hex bar mounted in the three jaw 6" chuck and a 1/2" drive rattle gun. But i digress, now back to the draw bar.

For whatever reason occurred to me at the time i resolved to have a right hand thread on one end and a left hand thread at the other end, and with the confidence misplaced by the experience with the back plate decided to undertake the more difficult of the two tasks, that is to turn a left hand thread on a spindle threaded back plate chuck with no other locking mechanism save the seized back plate. So off to the Nuts and Bolts supplier for a 1" nut (about eight dollars two years ago) whereupon I returned with a left hand nut.

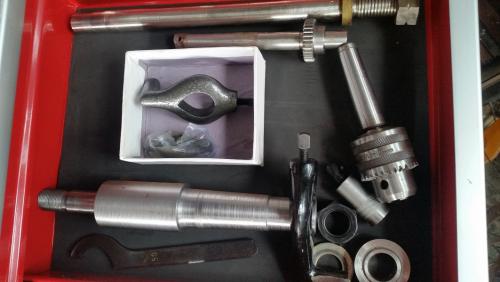

Here is the picture of the machined part and said bought nut.

Unfortunately the draw the draw bar made no more head way than precious attempts so i resolved to do the following, with VERY light cuts: .

.

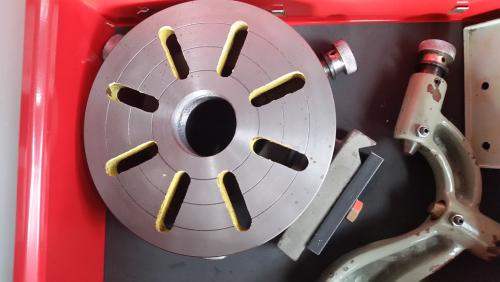

Fortunately the lathe came with a 8.25" threaded face plate and a 8.5" four jaw chuck mounted on its own threaded back plate:

and

and

In home workshop machining of a new back plate for the 6" 3 jaw chuck is in the works. In the meantime the four jaw chuck is used. Need to make the spacers tool jacks and clamp down tools for the face plate but have the dogs and Dividing head for the hole circle holes placement. and

and

.

.

If the back plate was not removed the Head stock could not be dismantled, the bull gear (driving the back gears) could not be repaired and the bearings and seals could not be replaced. (Projects forum - Lathe Bearings and Seals replaced).

Will update this thread as i progress the machining.

john aka castellated nut

Being a relative newbie, although i had some experience back around late 1960's at Repco with brake lathes, i took up a course in u-tubing and lo and behold to my amazement i retained enough knowledge offered by the many savants to tread very carefully through this metal minefield. Spindles are precious.

Long story short, my first machining job made sense whilst the spindle's 8TPI 2.25" thread was well and truly seized the back plate. The project was to make a 1" draw bar (the largest material on hand) in an attempt to wrestle the back plate off the spindle. As it turned out even with one metre (oops one meter - for our American friends) breaker bar on one end and a three meter (i'm learning) piece of 2" dia. thick walled galvanized work pipe on the other end there was no movement no matter what was done. Including using a 1" hex bar mounted in the three jaw 6" chuck and a 1/2" drive rattle gun. But i digress, now back to the draw bar.

For whatever reason occurred to me at the time i resolved to have a right hand thread on one end and a left hand thread at the other end, and with the confidence misplaced by the experience with the back plate decided to undertake the more difficult of the two tasks, that is to turn a left hand thread on a spindle threaded back plate chuck with no other locking mechanism save the seized back plate. So off to the Nuts and Bolts supplier for a 1" nut (about eight dollars two years ago) whereupon I returned with a left hand nut.

Here is the picture of the machined part and said bought nut.

Unfortunately the draw the draw bar made no more head way than precious attempts so i resolved to do the following, with VERY light cuts:

Fortunately the lathe came with a 8.25" threaded face plate and a 8.5" four jaw chuck mounted on its own threaded back plate:

In home workshop machining of a new back plate for the 6" 3 jaw chuck is in the works. In the meantime the four jaw chuck is used. Need to make the spacers tool jacks and clamp down tools for the face plate but have the dogs and Dividing head for the hole circle holes placement.

If the back plate was not removed the Head stock could not be dismantled, the bull gear (driving the back gears) could not be repaired and the bearings and seals could not be replaced. (Projects forum - Lathe Bearings and Seals replaced).

Will update this thread as i progress the machining.

john aka castellated nut

to the forum SKL001.

to the forum SKL001.

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)