Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

I think this is what Ed's looking for or something close to it.

gear.xls

gear.xls (Size: 297 KB / Downloads: 21)

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

Posts: 2,629

Threads: 101

Joined: Dec 2014

Location: Michigan

Here's the formula for the tpi of your gears.

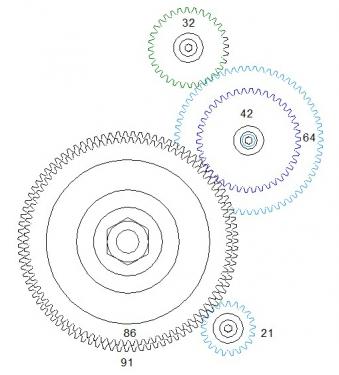

From your pic, I'm going to number (letter) your gears.

A: 32

B: 64

C: 42

D: 91

E: 86

F: 21

X: 0.94545

Y: LS TPI (8 in your case)

(B/A) * (D/C) * (F/E) * Y * X = TPI.

A word about X. X is the Kludge factor since the 32 tooth gear isn't spinning at the same speed as the spindle. X is actually 32/S with S being the number of teeth on the spindle's gear.

I haven't looked at the XLS that Dallen posted, but one thing you need to take into consideration is the distance between the lead screw gear and the 32 tooth stud gear - it could be that they don't mesh or they don't fit.

I'm pretty sure I have my math right, you'll wanna double check it.

Posts: 8,890

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

(04-29-2017, 04:31 PM)Vinny Wrote: Here's the formula for the tpi of your gears.

From your pic, I'm going to number (letter) your gears.

A: 32

B: 64

C: 42

D: 91

E: 86

F: 21

X: 0.94545

Y: LS TPI (8 in your case)

(B/A) * (D/C) * (F/E) * Y * X = TPI.

A word about X. X is the Kludge factor since the 32 tooth gear isn't spinning at the same speed as the spindle. X is actually 32/S with S being the number of teeth on the spindle's gear.

I haven't looked at the XLS that Dallen posted, but one thing you need to take into consideration is the distance between the lead screw gear and the 32 tooth stud gear - it could be that they don't mesh or they don't fit.

I'm pretty sure I have my math right, you'll wanna double check it.

Vinny,

The 86 tooth gear is used for metric threads only and the 91 tooth is for imperial threads only. As drawn in the image, just the 91 tooth gear is engaged with other gears. It's kind of hard to see that in the image since the gears are so close in diameter. The 86 tooth gear is just along for the ride since the two form a compound gear.

Also, doesn't the gearing in the gear box have to be included in the formula somehow? The 21 tooth gear would be driving the gears in the gear box which in turn drive the lead screw.

Ed

Posts: 2,629

Threads: 101

Joined: Dec 2014

Location: Michigan

By showing change gears I figured you opted for a cheaper model than one with a gearbox. I'll do some more figgerin.

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

even with the quick change box on the lathe there are still thread pitches that you will need to change gears to be able to turn them

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

Posts: 8,890

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

(04-29-2017, 09:06 PM)dallen Wrote: even with the quick change box on the lathe there are still thread pitches that you will need to change gears to be able to turn them

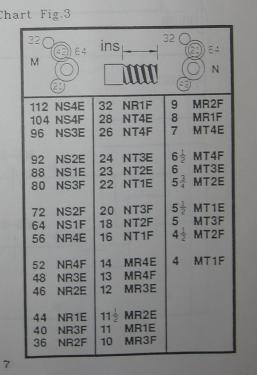

Oh, I already know that. I'm looking to find every possible thread pitch my lath is capable of. If I have to change gears, then so be it.

Ed

Posts: 4

Threads: 0

Joined: Jun 2017

Location: New Zealand

Hello EdK,

I have just sent you an E-mail but have now found the program I talked about online so here is the link.

http://lathegears.software.informer.com/

This program is the best thing since sliced bread and I am sure you will like it.