Posts: 536

Threads: 39

Joined: Jan 2013

Location: Kelowna, BC, Canada

Two years after the fire, I finally got a computer to move the steppers on my X2 CNC mill. Lots of fun guessing at what to try next when you're working out of a downloaded off-shore translated manual which didn't actually come with the control board. The only problem I've seen now is that I can't move the X-axis to the positive (right) side using the keyboard arrow or the plug-in remote made for Mach 3.

The Y and Z axes and the X-axis negative (left) all work fine when controlled by the arrow and Pg Up/Pg Dn keys and the remote. All functions work properly when controlled by a G-code routine, including the X+.

I'm convinced that it's Mach 3 that's doing it because , when I turn off the power to the control board, the Mach 3 displays for all the axes will increment and decrement to the key and remote inputs except the X+.

Has anyone had this happen one their machines? Any solutions would be appreciated. Mach 3 has gone to a semi-automated support system, so it'll take a while to get any help from them.

Thanks, guys.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

Posts: 739

Threads: 35

Joined: Feb 2012

Location: Minneapolis, MN

I do not have nor have ever used Mach-3. But I did stay in a Holiday Inn ... Oh, never mind, the first part is true but I slept in my own bed last night.

Just thinking out loud here.

Terms:

pendant - the plug-in remote

controller - the piece between the PC running Mach-3 and the servo\stepper drivers

X+ works if it is a G-code command. This suggests that the parallel port on the PC can talk to the controller without any issues. It also suggests that at least parts of Mach-3 are able to manipulate the parallel port ... i.e. if Mach-3 is using the G-code as the source for movement commands then things work fine.

X+ does not work if the source for movement commands is the keyboard or the pendant. If it were just the keyboard or just the pendant I would suspect a hardware failure but is it both so I would initially dismiss that possibility.

Which brings us to "inside Mach-3 the 'manual stimulus' for an X+ movement is not being interpreted correctly".

Again, my knowledge is based on looking at the manual, but I'd review section "5.3 Defining input and output signals that you will use" and see if there is something that "seems to be different than the others", like an emulator turned ... "5.3.3 Emulated input signals" ... or ... "5.3.5 Defining encoder inputs" ... or maybe ... "5.6.2 Configure System Hotkeys" ... or ???

Maybe see if "6.2.3 'Move to' controls" ... a truly lame paragraph but you might be able to figure out what it really means ... to see if it is just the jog buttons that do not go X+ or if it is any manual stimulus for X+ that is being ignored.

Maybe try "5.3.8 Testing" and see if the diagnostic screen allows you to see the status of the inputs ... i.e. something lights up when the keyboard or the pendant provide stimulus.

Just thoughts off the top of my head and looking at the manual for the first time. No actual Mach-3 experience.

Arvid

Posts: 536

Threads: 39

Joined: Jan 2013

Location: Kelowna, BC, Canada

It turns out that the parallel port driver was a bit screwy. To fix it, you have to load a fresh copy of the Mach 3 software and then unlock it with your license key file.

I got past that issue, but now I have a new one. I was trying to confirm the accuracy of the table movements. I set a 4" gauge block on the table, lined up one end on the spindle centre line. When I moved the table in the X-axis, the display showed about three times the correct distance at the other end. Something for another day.

Now, I should start designing all the parts I figured would be best done on a CNC. Getting closer every day.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

Posts: 739

Threads: 35

Joined: Feb 2012

Location: Minneapolis, MN

Glad you found what was wrong but I find it strange that G-code made it thru the driver without any issues but manual commands did not. By the time it makes it to the driver it should have been source agnostic. But maybe the software architecture is not what I would envision it to be.

Oh well, at least it is working.

Posts: 536

Threads: 39

Joined: Jan 2013

Location: Kelowna, BC, Canada

Today I got to wondering whether the trouble I had yesterday with the Mach 3 display advancing a LOT faster than the table was moving while I was controlling it from the keyboard or pendant would go away when it was running from G-code.

Yup. Verily.

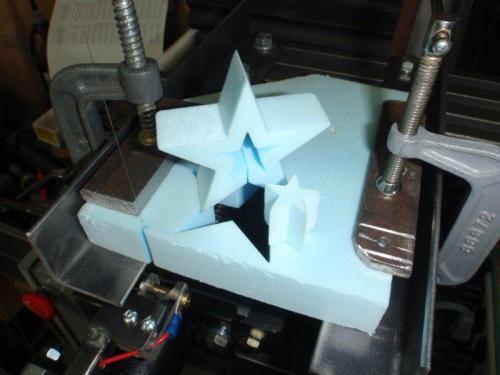

I restored all the motor settings I had been using before the fire and ran a routine I had written to test the hot-wire attachment I had made for it. Here's the result back then:

Today, I printed out the original drawing to scale and measured it against the design dimensions. Accurate to the nearest thou. I attached the drawing to the table and lined up a pointer in the spindle. It traced the line perfectly.

So now it's worth pressing ahead with designing all the thingies that this machine can make easiest. I also have to make a new hot-wire attachment. I told the 'restoration' company I wanted it back, but they obviously threw it out. The hot-wire will be a great tool for prepping for lost-foam castings.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

Nice work Mike - glad to see that you are getting things back together.

Hunting American dentists since 2015.

Posts: 691

Threads: 14

Joined: Feb 2015

Location: Oakland, California

If you added a 2-axis tilt to your hot-wire machine, you could get the foam patterns directly off the CNC **with draft** already in them!! How awesome would that be? Unless, of course, you are using the lost foam method, then it wouldn't matter.

Posts: 536

Threads: 39

Joined: Jan 2013

Location: Kelowna, BC, Canada

I've had better results with lost foam than sand casting, but that would be a good idea for multiple copies. Everything's a possibility.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.