Posts: 4,495

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

You got it Jerry.

For your hex, cut a flat - rotate 60°, cut a flat - rotate 60° etc., etc.

Willie

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

Wait guys, if I read correctly he's not arguing about how many degrees are in a circle, he said :-

(04-12-2012, 01:30 PM)ETC57 Wrote: As you can see my rt dose not fit squarely on my little mill.

Jerry

P.S. All helpful input is welcome please.

Jerry, I'm sorry but from that photo I cannot see that your rt does not fit squarely on your machine. Please elaborate.

Steve

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 4,495

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

I believe Jerry is referring to establishing the "zero" mark on his ro-tab to align with the X or Y axis on his machine table. Notice how the hand wheel (and indicator plate) is sitting at a 45° angle to the table travel?

It doesn't need to be square to the table though to cut equal features that will run the full 360° on a simple part. You can start at any point as long as no one particular feature needs to aligned at a specific point on the part.

As long as you have equal divisions, 0 - 60 - 120 - 180 - 240 - 300 it will come out OK no matter which way "zero" is pointing when you begin.

I have the same issues on my drill press table. The spacing of the T-slots don't jive with the spacing of the mounting tabs on my ro-tab or my indexer. Standards? What standards???

Of course I could be totally wrong

(sure wouldn't be the first time) and Jerry means something else entirely!

Willie

Posts: 576

Threads: 18

Joined: Feb 2012

Location: Washington State USA

Yup Willie,

You hit the nail right on the head!

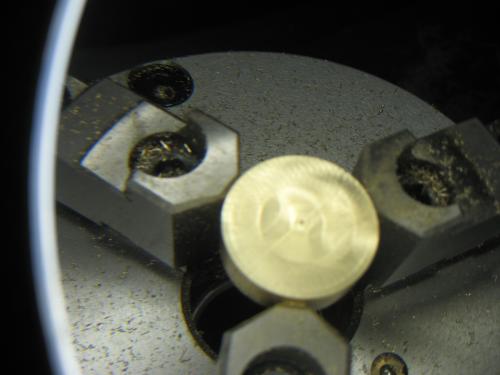

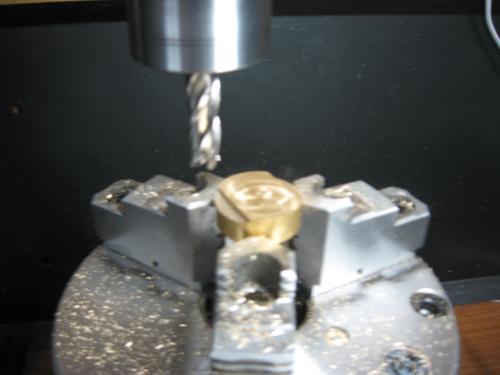

By the way I got it done see.

Jerry.

ETC57, proud to be a member of MetalworkingFun Forum since Feb 2012.

Posts: 4,495

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

(04-12-2012, 09:23 PM)ETC57 Wrote: By the way I got it done see.

Jerry.

I never had a doubt Jerry!

Now.....

What is it??? I can't really tell the size from the pictures, but it looks like a spark plug tube nut to me?

Willie

Posts: 576

Threads: 18

Joined: Feb 2012

Location: Washington State USA

OOOOOOO that!!

Well it's a lower steering column bushing for a riding lawnmower,

the hex head is how the manufacture decided to keep it from spinning.

There is a corresponding hole in the chassis that it fits in to.

The original bushing is nylon and impossible to get, this should out live the mower!

Thank's guy' for all your help!!!

Jerry.

ETC57, proud to be a member of MetalworkingFun Forum since Feb 2012.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Jerry,

Nice one

DaveH

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

You have to love these over engineered fixes, I do them all the time too. Some day an archaeologist will dig up a rusted pile of junk, with one beautifully preserved bushing. Nice work Jerry.

Greg

Free advice is worth exactly what you payed for it.

Greg