Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

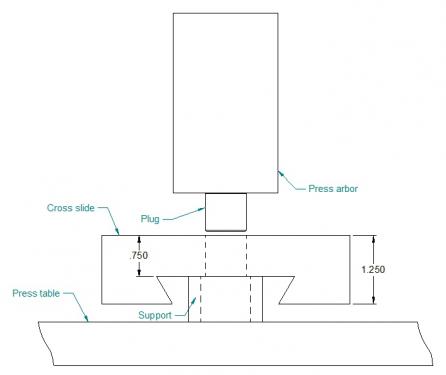

Do you think I need to support the cross slide, as shown in the first image, when I press the plug in? Or is the 3/4" thick cast iron strong enough to handle the pressure unsupported, as in the second image?

Thanks,

Ed

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

I'd support it, very unlikely you'd crack the cross slide without support but if you did you'd never be able to kick yourself hard enough. The support shouldn't need to he hollow as in your sketch, doesn't the plug sit flush on the bottom?

Free advice is worth exactly what you payed for it.

Greg

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

The following 1 user Likes EdK's post:

stevec (06-14-2014)

(06-13-2014, 05:00 PM)f350ca Wrote: I'd support it, very unlikely you'd crack the cross slide without support but if you did you'd never be able to kick yourself hard enough. The support shouldn't need to he hollow as in your sketch, doesn't the plug sit flush on the bottom?

Thanks Greg, I suspected that would be the answer so I just got done making the support. I assume aluminum is fine.

It needs to be hollow because I made the plug about .050" over in length so I can press it flush to the top of the cross slide then mill the bottom side down enough to take a light skim of the cross slide guaranteeing the plug and cross slide surfaces are on the same plane for mounting the lead screw nut.

Ed

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

Like Greg, I'd support it as well. No point risking that 1 in a million crack!

Hunting American dentists since 2015.

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

I made some progress on the cross slide today. I got the plug pressed in and the three holes almost done. The middle of the three is supposed to be threaded for a set screw and I grabbed the wrong drill bit and drilled it for a clearance fit instead of a tap drill. Not a big deal, I'll just use a M6x1 instead of the 10-32 I was going to use. I still need to slot the screw shank hole in the left hole. I've got the screw head hole slotted but couldn't slot the shank hole in the same setup so I need to flip it over and mill that from the bottom side.

Ignore the far right hole. It's for a Gits oiler and not part of the cross slide fix.

Ed

EDIT: I guess I didn't screw up the hole for the set screw. I went to drill it out for a M6 tap size and realized I hadn't drilled it larger than a tap size for a 10-32 thread. So now the hole is tapped for the 10-32 set screw.