09-11-2016, 09:11 PM

While I was still out of my house after the fire (2 years ago last Saturday), I picked up a Clarckson Tool and Cutter Grinder from a friend. For some reason, if seemed like a good idea to make a radius attachment for it, patterned after the Clarckson Mark II. I got started on it a couple of months ago and got a bit delayed when my shoulder broke suddenly on the way to a ditch. I managed to resume a few weeks ago, but progress was pretty slow because I could only work for a short time before I got too tired. Anyway, I got it finished on Friday, so I'll give you a quick rundown on the process.

Here's a look at the commercially made version, as seen on eBay.

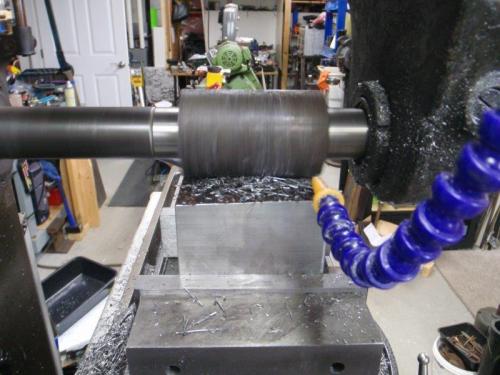

My version started with a block of steel for the main body. I squared it up on the horizontal mill.

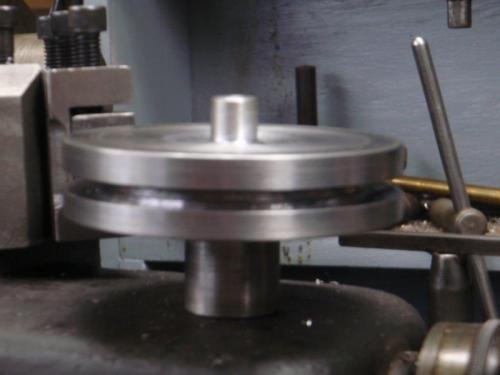

Next came the rotating disk that carries the working parts, complete with a dovetailed groove running around the rim.

Truing up the body block for dead centre in the 4-jaw. I like the long wiggler for this type of work.

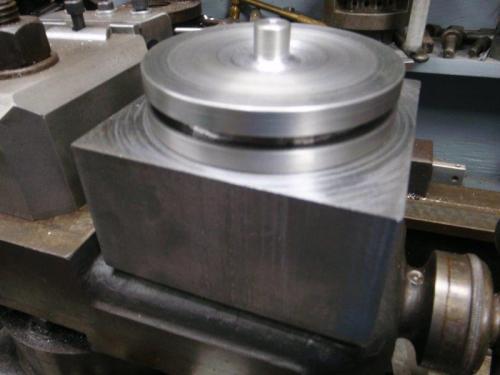

The disk fitted to the body block.

Cutting curved slots in one of the side walls for the base plate.

Oh, all right! Jump ahead to the finished attachment, set up to sharpen a 1" 2-flute ball-end mill. I opted to use the universal head from the Clarckson grinder. I might make a few more pieces at a later date.

And the cutter after the first pass at the secondary bevel.

Here's a look at the commercially made version, as seen on eBay.

My version started with a block of steel for the main body. I squared it up on the horizontal mill.

Next came the rotating disk that carries the working parts, complete with a dovetailed groove running around the rim.

Truing up the body block for dead centre in the 4-jaw. I like the long wiggler for this type of work.

The disk fitted to the body block.

Cutting curved slots in one of the side walls for the base plate.

Oh, all right! Jump ahead to the finished attachment, set up to sharpen a 1" 2-flute ball-end mill. I opted to use the universal head from the Clarckson grinder. I might make a few more pieces at a later date.

And the cutter after the first pass at the secondary bevel.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

and nicely shown as well

and nicely shown as well