06-07-2024, 01:42 PM

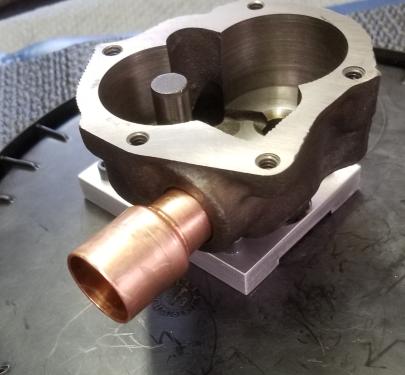

Swaged a copper fitting to increase the OD so I can press it into my oil pump pickup for my pre-luber.

Needing a pump pickup tube to reach the bottom of my bucket, I found a copper reducer fitting was "just" a bit to small to press into the hole on the pump. So I chucked it up in the lathe... spun a boring bar around backwards in the tool holder...rotated the tool post slightly so I had a "point contact" on the ID of the fitting...greased it up and rode the tool out while the fitting rotated at slowish RPM. Basically a metal spinning operation in miniature.

Grew the OD just enough to be a press fit into the pump pickup hole. Few more pieces still needed to extend to the bottom of the bucket.

I hope it has enough suck to lift the oil

Needing a pump pickup tube to reach the bottom of my bucket, I found a copper reducer fitting was "just" a bit to small to press into the hole on the pump. So I chucked it up in the lathe... spun a boring bar around backwards in the tool holder...rotated the tool post slightly so I had a "point contact" on the ID of the fitting...greased it up and rode the tool out while the fitting rotated at slowish RPM. Basically a metal spinning operation in miniature.

Grew the OD just enough to be a press fit into the pump pickup hole. Few more pieces still needed to extend to the bottom of the bucket.

I hope it has enough suck to lift the oil

Retired old guy finally living the dream and enjoying life to the fullest!!!