05-27-2024, 02:43 PM

I've been working on improving my mini lathe to increase rigidity. Eliminating the compound mechanism when it's not needed is the obvious first step. Now I'm working on the cross slide assembly.

I've 3D printed parts that I want to make to be sure I get the dimensions correct since steel is pricey and I don't want to/can't afford to screw up.

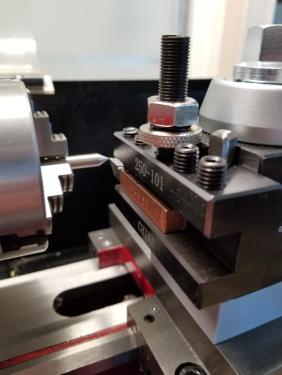

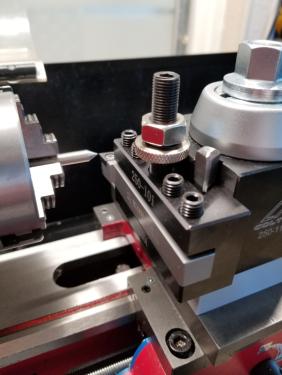

I wanted the tool holder to be adjustable when using either 3/8" or 1/2" tooling. It came out perfect with enough of an adjustment range for both to work.

I got a piece of bronze to make the new gib out of. I've ordered the steel for the two other parts.

Ed

3/8" tooling check - 1/2" tooling check

I've 3D printed parts that I want to make to be sure I get the dimensions correct since steel is pricey and I don't want to/can't afford to screw up.

I wanted the tool holder to be adjustable when using either 3/8" or 1/2" tooling. It came out perfect with enough of an adjustment range for both to work.

I got a piece of bronze to make the new gib out of. I've ordered the steel for the two other parts.

Ed

3/8" tooling check - 1/2" tooling check