Hi Guys,

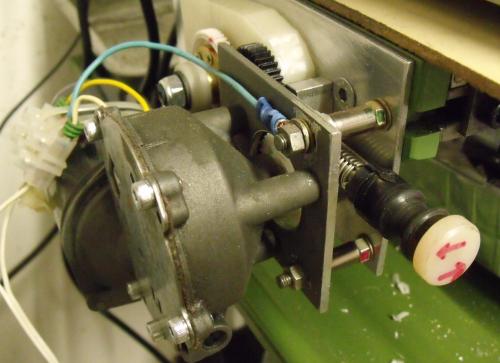

Some time ago I made a power feed for my mill table ! I also used a window screen wiper motor, salvaged from a scrap yard car. I actually have a couple of them that I also salvaged. Note that there are both left hand and right hand ones. I use a variable voltage/current power supply to feed my motor. It can supply 0 v up to 30 volts at up to 5 amps. The fact that the power supply is fully metered is very handy, because you can monitor the performance and progress of the machining.

I used gears to drive the leadscrew and added a Tumbler Gear mechanism, so I can have forward neutral and reverse movement of the table. Part of this is because I discovered that the window screen wiper motor is intended to run in one direction only, so reversing the power supply polarity to make it run in the opposite direction could create a future problem.

All the gears are plastic ones salvaged from printers and photocopiers. Only one gear needed extensive modifications to make it suitable for driving the leadscrew. I didn't make any modifications or changes to the mill leadscrew. I did make a new hub to replace the table handle on the left hand side. I retained the handle on the right hand side because it was convenient for traversing the table by hand when the tumbler gears were in neutral.

One advantage I did find was that since I had covered up the table locking screws when I fitted the DRO scale to the table front, was putting the power feed into gear would stop the table from moving when using the front hand wheel to cut an edge.

This is the new hub that I made to replace the left hand handle.

The plastic gear is bolted onto this hub.

The brass ring was made for the purpose of reinforcing the clamping of the plastic gear.

Some time ago I made a power feed for my mill table ! I also used a window screen wiper motor, salvaged from a scrap yard car. I actually have a couple of them that I also salvaged. Note that there are both left hand and right hand ones. I use a variable voltage/current power supply to feed my motor. It can supply 0 v up to 30 volts at up to 5 amps. The fact that the power supply is fully metered is very handy, because you can monitor the performance and progress of the machining.

I used gears to drive the leadscrew and added a Tumbler Gear mechanism, so I can have forward neutral and reverse movement of the table. Part of this is because I discovered that the window screen wiper motor is intended to run in one direction only, so reversing the power supply polarity to make it run in the opposite direction could create a future problem.

All the gears are plastic ones salvaged from printers and photocopiers. Only one gear needed extensive modifications to make it suitable for driving the leadscrew. I didn't make any modifications or changes to the mill leadscrew. I did make a new hub to replace the table handle on the left hand side. I retained the handle on the right hand side because it was convenient for traversing the table by hand when the tumbler gears were in neutral.

One advantage I did find was that since I had covered up the table locking screws when I fitted the DRO scale to the table front, was putting the power feed into gear would stop the table from moving when using the front hand wheel to cut an edge.

This is the new hub that I made to replace the left hand handle.

The plastic gear is bolted onto this hub.

The brass ring was made for the purpose of reinforcing the clamping of the plastic gear.