Mine has never cut very straight. It's better than when I got it, but I haven't really fussed with it too much. Nice finish on the casting.

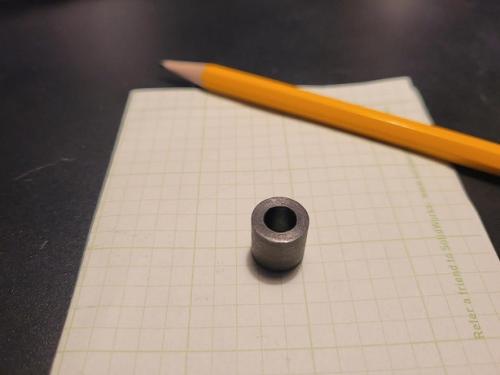

Buddy texted me that he needed a bushing for one of those weed whackers with the swinging blades. Sent the dimensions, and I agreed. I found a piece of mystery steel in my stash and got to work.

Bore (reamed) is spot on. Length is as well. Outer diameter is just shy of a thou undersized, but I figure it should do the trick. I blued it, just because.

I.D. is .250, O.D. is .471, Length is .452.

Ed, while I was parting off, I remembered your comment about it. I think the secret on small machines is just to go for it, and not try to baby it so much. I did get a catch, and hit the e-stop, but going in slowly to remove the burr and then continuing on, it made the cut just fine.

Buddy texted me that he needed a bushing for one of those weed whackers with the swinging blades. Sent the dimensions, and I agreed. I found a piece of mystery steel in my stash and got to work.

Bore (reamed) is spot on. Length is as well. Outer diameter is just shy of a thou undersized, but I figure it should do the trick. I blued it, just because.

I.D. is .250, O.D. is .471, Length is .452.

Ed, while I was parting off, I remembered your comment about it. I think the secret on small machines is just to go for it, and not try to baby it so much. I did get a catch, and hit the e-stop, but going in slowly to remove the burr and then continuing on, it made the cut just fine.

Full of ideas, but slow to produce parts