10-06-2022, 08:54 PM

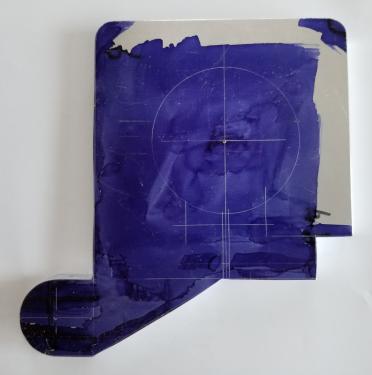

Today I worked on the quill stop for the mill. I set up the HF band saw in the vertical position and attached the table to cut out the outline from the aluminum plate. It was slow going at first so I changed the speed to the fastest pulley. That didn't help much so I changed out the original blade with a replacement blade that I had bought for the saw. The original blade that came with the saw has too many teeth per inch for cutting aluminum. The new blade has a 10/14 tooth configuration. That worked much better.

Then I attacked the plate with files to roughly create the rounded features. I'll fine tune them later. It's to the point where I can mount it onto the mill table and mill the straight sides to clean them up. Then I'll start cutting the large hole that clamps over the spindle housing. I think I'll start with a hole saw and then go to the final dimension with a boring head.

Ed

Then I attacked the plate with files to roughly create the rounded features. I'll fine tune them later. It's to the point where I can mount it onto the mill table and mill the straight sides to clean them up. Then I'll start cutting the large hole that clamps over the spindle housing. I think I'll start with a hole saw and then go to the final dimension with a boring head.

Ed