07-04-2012, 01:00 PM

(This post was last modified: 07-04-2012, 01:19 PM by henryarnold.)

Once I finished making my mounting plate, I did a dry check on my cross slide to make sure everything lined up OK. I also marked where the mounting holes on the cross slide needed to be drilled and tapped.

I drilled and tapped the cross slide mounting holes by clamping the cross slide to an angle plate on the mill. The distance between the holes had to be accurate because I did not allow for any movement in the length ways direction. I made both my slots in the up and down direction for adjusting the scale accurately with the movement of the cross slide.

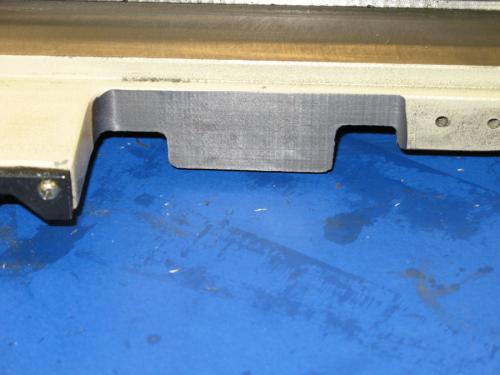

Here's the plate screwed to the cross slide. The fit was good and there's 0.100" of up and down movement possible for adjustment which I'll show later.

The surface on my carriage where the scale pickup will mount to was cast crooked and at an angle. It would be difficult to shim it in a way that would create a clean mounting of the pickup. I decided to remove the carriage and mill the area square and at right angles to the top of the cross slide. I mounted the carriage on my mill registering off of the dovetail. I milled about 0.050" which was enough to create a square mounting surface. There was plenty of meat to my carriage so the 0.050" won't be missed.

Here's a close up of the milled area before I drilled and tapped it for the pickup bracket.

I had to do my drilling and tapping of the carriage in a vise because I couldn't come up with a way to mount it on my mill because of it's size.

I drilled and tapped the cross slide mounting holes by clamping the cross slide to an angle plate on the mill. The distance between the holes had to be accurate because I did not allow for any movement in the length ways direction. I made both my slots in the up and down direction for adjusting the scale accurately with the movement of the cross slide.

Here's the plate screwed to the cross slide. The fit was good and there's 0.100" of up and down movement possible for adjustment which I'll show later.

The surface on my carriage where the scale pickup will mount to was cast crooked and at an angle. It would be difficult to shim it in a way that would create a clean mounting of the pickup. I decided to remove the carriage and mill the area square and at right angles to the top of the cross slide. I mounted the carriage on my mill registering off of the dovetail. I milled about 0.050" which was enough to create a square mounting surface. There was plenty of meat to my carriage so the 0.050" won't be missed.

Here's a close up of the milled area before I drilled and tapped it for the pickup bracket.

I had to do my drilling and tapping of the carriage in a vise because I couldn't come up with a way to mount it on my mill because of it's size.

henryarnold, proud to be a member of MetalworkingFun Forum since Apr 2012.