04-11-2019, 02:52 AM

Got some more done on the frankenmill:

I drilled the two long holes through the top plate for the 5/8 nf x 8" bolts. I did the first one in my crappy drill press, which has about 40mm quill travel. Then I realised I have a drilling machine with a fair bit more travel than that:

The long drill did not make for a very straight hole over 5 1/2", fortunately I had a 5/8 straight reamer that cleaned them up enough for the bolt to go through.

Next job was to grind the front surface of the nose piece, this was referenced to the depth of the step where the tilt gear mounts, to ensure correct mesh of the gear set.

Gotta love the surface grinder; correct depth to within 0.01mm and this finish.

I removed the vertical attachment (REALLY for the last time...I hope!) and re-inserted the overarm with the cheek plates, then bolted the top plate on

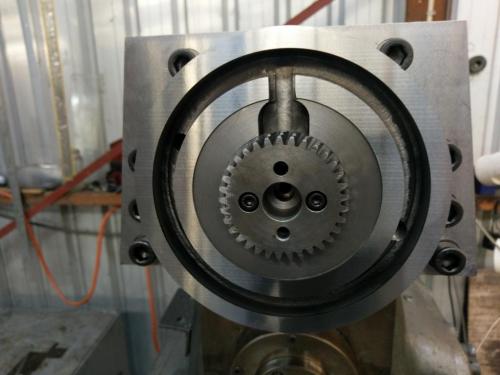

Assembled the nose piece to the front plate

and mounted the nose assembly

I seem to have miscalculated something here, the 8" long top bolts bottomed out. Easiest thing will be to make some thick washers I think.

I filed the damaged teeth of the tilt adjustment gear so they won't bind if I ever turn the head upside down. I've rotated the gear 180 degrees so undamaged teeth will be in use. Mounted the gear, which also serves as the spigot for the J-head. Roll pin not installed yet.

then at about 4pm this afternoon, schoolgirl-like giggling could be heard coming from my workshop...

Lots of work to do yet, I have not taken any tram readings at all but I expect there'll be quite a task to get the tilt set up accurately. Then everything will be disassembled again and painted. And there's the VFD and the mach tach to set up.

I drilled the two long holes through the top plate for the 5/8 nf x 8" bolts. I did the first one in my crappy drill press, which has about 40mm quill travel. Then I realised I have a drilling machine with a fair bit more travel than that:

The long drill did not make for a very straight hole over 5 1/2", fortunately I had a 5/8 straight reamer that cleaned them up enough for the bolt to go through.

Next job was to grind the front surface of the nose piece, this was referenced to the depth of the step where the tilt gear mounts, to ensure correct mesh of the gear set.

Gotta love the surface grinder; correct depth to within 0.01mm and this finish.

I removed the vertical attachment (REALLY for the last time...I hope!) and re-inserted the overarm with the cheek plates, then bolted the top plate on

Assembled the nose piece to the front plate

and mounted the nose assembly

I seem to have miscalculated something here, the 8" long top bolts bottomed out. Easiest thing will be to make some thick washers I think.

I filed the damaged teeth of the tilt adjustment gear so they won't bind if I ever turn the head upside down. I've rotated the gear 180 degrees so undamaged teeth will be in use. Mounted the gear, which also serves as the spigot for the J-head. Roll pin not installed yet.

then at about 4pm this afternoon, schoolgirl-like giggling could be heard coming from my workshop...

Lots of work to do yet, I have not taken any tram readings at all but I expect there'll be quite a task to get the tilt set up accurately. Then everything will be disassembled again and painted. And there's the VFD and the mach tach to set up.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Milling Machine (n); a machine tool used in the production of lathe components.