12-19-2018, 04:15 AM

(This post was last modified: 12-19-2018, 04:17 AM by Pete O.

Edit Reason: spelling

)

I didn't manage to get to this project at all yesterday, too many pre-Christmas chores aroud the place. I got a couple of hours in this afternoon and got the rear end of one of the cheek plates radiused.

This is the setup on the rotary table

That's the first time I've run coolant onto this RT, the rim sure contains the mess. It drains back through the centre hole of the RT onto the mill table. I'm running the coolant from the lathe, one feed hose and one drain hose snaking around the place.

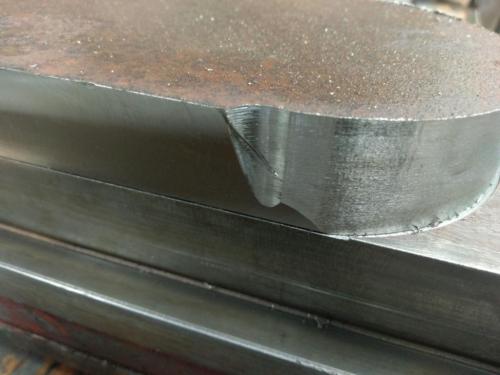

Using a 1" diameter roughing end mill. I decided I was happy with the finish from the rougher as this surface is going to be painted. Feeding the Y-axis in for a final pass, my clamping arrangement let go, resulting in one gouge mark and a radius .040 larger than intended. The radius is not a problem- it's intended to follow the line taken by the fly-cutter on the side of the overarm for the sake of appearance. Ended up ok, but I'll have to dress that gouge mark out.

Clamping large-ish items to the RT is problematic with the two broken areas in the T-slots. The breaks always seem to turn up right where I don't need them. This part is fit for purpose so far, might see if I can come up with a more secure arrangement for the other side.

This is the setup on the rotary table

That's the first time I've run coolant onto this RT, the rim sure contains the mess. It drains back through the centre hole of the RT onto the mill table. I'm running the coolant from the lathe, one feed hose and one drain hose snaking around the place.

Using a 1" diameter roughing end mill. I decided I was happy with the finish from the rougher as this surface is going to be painted. Feeding the Y-axis in for a final pass, my clamping arrangement let go, resulting in one gouge mark and a radius .040 larger than intended. The radius is not a problem- it's intended to follow the line taken by the fly-cutter on the side of the overarm for the sake of appearance. Ended up ok, but I'll have to dress that gouge mark out.

Clamping large-ish items to the RT is problematic with the two broken areas in the T-slots. The breaks always seem to turn up right where I don't need them. This part is fit for purpose so far, might see if I can come up with a more secure arrangement for the other side.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Milling Machine (n); a machine tool used in the production of lathe components.