09-29-2018, 08:34 AM

Today I welded the frame and bolted the motor down, then started some machining on the table. I'm going to borrow the mitre guide from my el-cheapo 300mm bandsaw, it's a piece of junk but it will do the job and will be easy to replace if it fails. It needs a 1/2" slot to slide in; I found a 1/2" x 5" side-and-face cutter amongst my collection, it looks like it is ready to be binned but it responded to a touch-up on the surface grinder with the sharpening jig I posted a while ago.

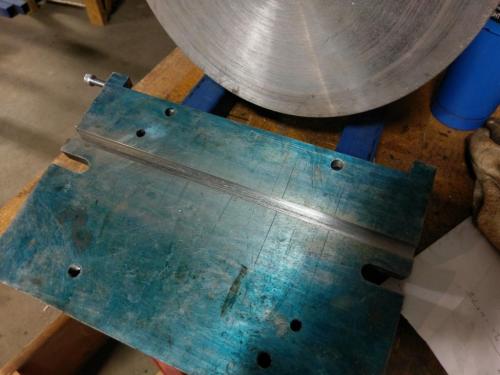

The slot was cut 1/4" deep, the sharpened cutter went through like butter. The photo is crap but the slot is good.

The table has to have a recess to fit around the disc, so that the pivot point for the table tilt can be as close as possible to the same plane as the front edge of the table. Cutting the recess was simple enough, but I scratched my head a bit over how to bevel the underside to 45 degrees. This is the setup I went with:

Nice to have enough room in the Z-axis to do this. I was also very thankful for the power feed on the knee; the bevel machining was all done in Z. It'll be a treat if I can ever get that J-head mounted on this machine so I can kick the stub-milling habit.

I got the machining on the table all finished before heading in for dinner tonight.

I'll be working on the table mounts next. I'd appreciate it if anyone who has a disc sander can tell me how much gap I should allow for the thickness of the sandpaper, I tried to buy a couple of sanding discs this morning but nowhere local has them.

The slot was cut 1/4" deep, the sharpened cutter went through like butter. The photo is crap but the slot is good.

The table has to have a recess to fit around the disc, so that the pivot point for the table tilt can be as close as possible to the same plane as the front edge of the table. Cutting the recess was simple enough, but I scratched my head a bit over how to bevel the underside to 45 degrees. This is the setup I went with:

Nice to have enough room in the Z-axis to do this. I was also very thankful for the power feed on the knee; the bevel machining was all done in Z. It'll be a treat if I can ever get that J-head mounted on this machine so I can kick the stub-milling habit.

I got the machining on the table all finished before heading in for dinner tonight.

I'll be working on the table mounts next. I'd appreciate it if anyone who has a disc sander can tell me how much gap I should allow for the thickness of the sandpaper, I tried to buy a couple of sanding discs this morning but nowhere local has them.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Milling Machine (n); a machine tool used in the production of lathe components.