07-19-2018, 06:12 AM

I had to make a pair of angle fixtures in order to be able to machine the sides of the overarm to accept a pair of cheek plates, these plates will be bolted to the sides of the overarm with another plate bolted down to the top of the cheek plates and the adaptor will be bolted to the front face of those three plates.

The two sides of the overarm casting are not planar surfaces but they are reasonably close to flat right at the front end where I need to attach stuff. The flat-ish surfaces are not quite at the same angle on the two sides

so I decided to split the difference and work to 80.5 degrees both sides.

I needed to make a pair of angled fixtures to clamp the overarm down onto. Found an offcut of the plate i used for the shaper table extension last year. Squared it up on the mill (this whole job is having to be done in stub-milling mode)

and then surfaced it in the shaper. Can't wait to get the frankenmill finished- the shaper is very slow with this sort of work

Split it on the bandsaw at something approaching the appropriate angle

I clamped the two halves together, drilled and reamed a couple of 12mm holes through them and dowelled them together so they could be milled as a matched pair.

Then I spent aaages setting up to mill the angle into them. Not having any guage blocks, I found a piece of scrap that was just over the required thickness and then used the surface grinder to get it down to the right thickness to set the sine bar up. As if the stub-milling business isn't awkward enough in itself, working at the back of the job all the time, the only sine bar I have is wider than the base of my vice so I had no end of stuffing about to get the sine bar in place to set the angle plate to the correct angle.

Clamped the pair of plates somewhere in behind all this so I couldn't see what I was doing and then milled them to the required angle plus a step to sit the side of the overarm dovetail against.

One day I'll get some good machinist squares but I reckon this was near enough for the purpose

drilled and counterbored to accept some half-inch socket-head capscrews;

Just to make this job drag out a bit, I couldn't get whitworth-threaded SHCS, all my T-nuts are 1/2" whitworth, had to use UNC capscrews and make some T-nuts to suit.

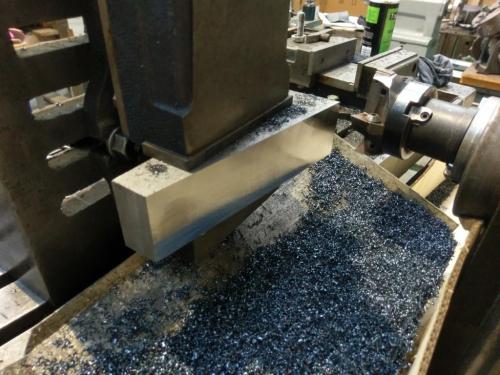

Finally got them bolted down to the mill table. When I say finally, I actually ended up having to move them forward so that the surface to be milled hung over the inside edge of the table, so I could use the outer t-slot to clamp it down, the overarm is too long to be able to clamp at the ends.

The end face of the fixtures was measured off the face of the column to get the step parrallel to the X-axis.

I milled one side of the overarm tonight, would you believe I forgot to take photos of the setup. I'll try and remember to take a photo when I do the other side.

The two sides of the overarm casting are not planar surfaces but they are reasonably close to flat right at the front end where I need to attach stuff. The flat-ish surfaces are not quite at the same angle on the two sides

so I decided to split the difference and work to 80.5 degrees both sides.

I needed to make a pair of angled fixtures to clamp the overarm down onto. Found an offcut of the plate i used for the shaper table extension last year. Squared it up on the mill (this whole job is having to be done in stub-milling mode)

and then surfaced it in the shaper. Can't wait to get the frankenmill finished- the shaper is very slow with this sort of work

Split it on the bandsaw at something approaching the appropriate angle

I clamped the two halves together, drilled and reamed a couple of 12mm holes through them and dowelled them together so they could be milled as a matched pair.

Then I spent aaages setting up to mill the angle into them. Not having any guage blocks, I found a piece of scrap that was just over the required thickness and then used the surface grinder to get it down to the right thickness to set the sine bar up. As if the stub-milling business isn't awkward enough in itself, working at the back of the job all the time, the only sine bar I have is wider than the base of my vice so I had no end of stuffing about to get the sine bar in place to set the angle plate to the correct angle.

Clamped the pair of plates somewhere in behind all this so I couldn't see what I was doing and then milled them to the required angle plus a step to sit the side of the overarm dovetail against.

One day I'll get some good machinist squares but I reckon this was near enough for the purpose

drilled and counterbored to accept some half-inch socket-head capscrews;

Just to make this job drag out a bit, I couldn't get whitworth-threaded SHCS, all my T-nuts are 1/2" whitworth, had to use UNC capscrews and make some T-nuts to suit.

Finally got them bolted down to the mill table. When I say finally, I actually ended up having to move them forward so that the surface to be milled hung over the inside edge of the table, so I could use the outer t-slot to clamp it down, the overarm is too long to be able to clamp at the ends.

The end face of the fixtures was measured off the face of the column to get the step parrallel to the X-axis.

I milled one side of the overarm tonight, would you believe I forgot to take photos of the setup. I'll try and remember to take a photo when I do the other side.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Milling Machine (n); a machine tool used in the production of lathe components.