08-02-2017, 05:29 PM

Hi Greg,

I’d never considered the clean-up advantages of non-routed cabinets, LOL, but you struck a nerve with that point !

Attempting to put a casserole dish of lasagna in the oven last night, it slipped out of my hands; the filling went EVERYWHERE: on me, on the oven, on the floor and on the routed edges of drawers and doors on the closest cabinet ! I was really unhappy, my dogs were really happy. Cleanup was PITA !

When I started woodworking about forty years ago, my first power tools were a 3/8 drill, a saber saw and a router. The first two were necessary but the router was definitely not. The initial efforts were horrible combinations of crude carpentry plus some French Colonial fou-fou using every shape cutter that I could lay hands on. There was no sense of style or continuity in any of the designs and the pieces would have looked much nicer if I’d thrown the router away !

Moving from the San Francisco area to my current location, I made a clean sweep of household goods and donated almost all of our (mismatched) furniture to Salvation Army. We slept on the floor and ate, sitting on the floor, for a while until I gradually built some furniture.

I’d already decided to keep things simple and thought about the kind of furniture in our old farmhouse, growing up in Tennessee. Apropos of that, during a visit to the local hardwood supplier, I found a fresh lot of Tennessee Cedar for something like $1.46/BF and the smell took me back to my childhood, ha-ha-ha.

The combination of wanting to simplify and finding the cedar suggested designs like these. The small chest of drawers and the night stand are Tennessee Cedar and Cherry – and you’re sure right about working Cherry and the way it takes a finish.

BTW, I made the base of the lamp, too, edge-gluing cedar with oak. Although the piece looks like it has been turned, it was actually made on a jointer - the glue joints, of course but also the rounded exterior shape.

These pieces were sprayed with water-base polyurethane, which I was experimenting with for the first time. I liked it OK but I’ve since gone back to oil base over a shellac or boiled linseed oil sealer.

This hope chest is Tennessee Cedar and Red Oak veneer. One of these days I’ll get rid of the hardware store latches and pulls and make some.

My California King bedstead is Tenneessee Cedar and brass tubing. I re-sawed 1 x 4 cedar planks into 3/16 “veneers” and glued them over Douglas Fir 2 x 4s since it wasn't possible to obtain anything bigger than 1 x 6 in cedar.

I could have glued up cedar planks to make up 2 x 4s but I had just about exhausted the supply of cedar by this time (there are a few other pieces of furniture that I didn’t photograph) so the option of gluing up cedar boards wasn’t available.

I didn’t use aged fir so there is some shrinkage at the end of the bed and every morning when I make the bed, I remind myself to plane the cedar high edges down. Hasn't happened yet.

(Incidentally, since Tennessee Cedar is VERY knotty, I warmed up some clear epoxy until it was very thin and then "painted" it into the knots to stabilize them. I waited a full week before beginning to saw the cedar.)

The only routing on any of these pieces, BTW, was some internal slotting for drawers and some slight corner-rounding and chamfering on external edges. Oh yeah, the wooden drawer pulls are almost entirely shaped on a large table router.

You mentioned using a 4-flute cutter and obviously it worked just fine but I would have thought a two-flute might clear chips better. Did you experience any burning ?

The top speed on my mill is even lower than yours, only3100 RPM. It works fine for molding cutters, dados and the like and I do use it for routing but for small cutters it just doesn’t work. The feed has to be so slow that burning is all but guaranteed.

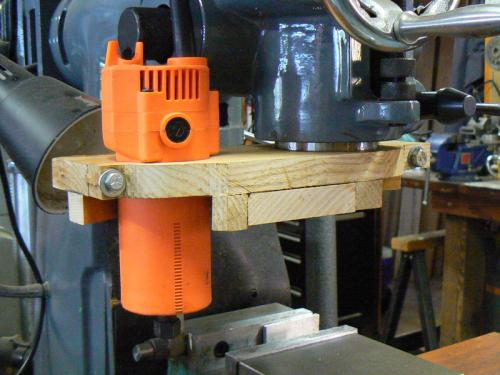

One day I got tired of that and threw this together in a couple of hours:

It clamps to the quill of the vertical mill and holds a $20 Harbor Freight trim router. All functions of the mill are preserved, X, Y, Z and quill downfeed. My problems with small router cutters were solved. The original intention was to check feasibility and then make a permanent metal holder. But, since it DOES work, motivation has been low. Maybe I'll paint it someday, LOL.

I was doing some work on a friend’s bathrooms, adding small custom molding around mirrors and tiles. He had a table saw and a drill and that was the extent of his woodworking tools.

I made this little portable rig to accommodate another cheap trim router so that I could make the molding on site. It clamps to any convenient flat surface. (A fence is easily fashioned by clamping a straight piece of stock to the table.)

I hope that this long post doesn’t violate any forum policy. This is partly a response to fc350a it also illustrates a few projects although they weren’t recent ones.

Cheers,

randyc

P.S. As of this date, I have NINE routers - I just hate to change cutters so there is a different one in each - but most are never used. My father-in-law, 93 years old and going strong, who is also a woodworker, hangs out at garage sales and picks up a router every time he sees one. Between the two of us, we must have twenty of them. But ninety percent of the time the ones that I use these days is a 3.5 horsepower Milwaukee on a table and the two little trim routers, ha-ha-ha. Seems like I've almost come full circle -

I’d never considered the clean-up advantages of non-routed cabinets, LOL, but you struck a nerve with that point !

Attempting to put a casserole dish of lasagna in the oven last night, it slipped out of my hands; the filling went EVERYWHERE: on me, on the oven, on the floor and on the routed edges of drawers and doors on the closest cabinet ! I was really unhappy, my dogs were really happy. Cleanup was PITA !

When I started woodworking about forty years ago, my first power tools were a 3/8 drill, a saber saw and a router. The first two were necessary but the router was definitely not. The initial efforts were horrible combinations of crude carpentry plus some French Colonial fou-fou using every shape cutter that I could lay hands on. There was no sense of style or continuity in any of the designs and the pieces would have looked much nicer if I’d thrown the router away !

Moving from the San Francisco area to my current location, I made a clean sweep of household goods and donated almost all of our (mismatched) furniture to Salvation Army. We slept on the floor and ate, sitting on the floor, for a while until I gradually built some furniture.

I’d already decided to keep things simple and thought about the kind of furniture in our old farmhouse, growing up in Tennessee. Apropos of that, during a visit to the local hardwood supplier, I found a fresh lot of Tennessee Cedar for something like $1.46/BF and the smell took me back to my childhood, ha-ha-ha.

The combination of wanting to simplify and finding the cedar suggested designs like these. The small chest of drawers and the night stand are Tennessee Cedar and Cherry – and you’re sure right about working Cherry and the way it takes a finish.

BTW, I made the base of the lamp, too, edge-gluing cedar with oak. Although the piece looks like it has been turned, it was actually made on a jointer - the glue joints, of course but also the rounded exterior shape.

These pieces were sprayed with water-base polyurethane, which I was experimenting with for the first time. I liked it OK but I’ve since gone back to oil base over a shellac or boiled linseed oil sealer.

This hope chest is Tennessee Cedar and Red Oak veneer. One of these days I’ll get rid of the hardware store latches and pulls and make some.

My California King bedstead is Tenneessee Cedar and brass tubing. I re-sawed 1 x 4 cedar planks into 3/16 “veneers” and glued them over Douglas Fir 2 x 4s since it wasn't possible to obtain anything bigger than 1 x 6 in cedar.

I could have glued up cedar planks to make up 2 x 4s but I had just about exhausted the supply of cedar by this time (there are a few other pieces of furniture that I didn’t photograph) so the option of gluing up cedar boards wasn’t available.

I didn’t use aged fir so there is some shrinkage at the end of the bed and every morning when I make the bed, I remind myself to plane the cedar high edges down. Hasn't happened yet.

(Incidentally, since Tennessee Cedar is VERY knotty, I warmed up some clear epoxy until it was very thin and then "painted" it into the knots to stabilize them. I waited a full week before beginning to saw the cedar.)

The only routing on any of these pieces, BTW, was some internal slotting for drawers and some slight corner-rounding and chamfering on external edges. Oh yeah, the wooden drawer pulls are almost entirely shaped on a large table router.

You mentioned using a 4-flute cutter and obviously it worked just fine but I would have thought a two-flute might clear chips better. Did you experience any burning ?

The top speed on my mill is even lower than yours, only3100 RPM. It works fine for molding cutters, dados and the like and I do use it for routing but for small cutters it just doesn’t work. The feed has to be so slow that burning is all but guaranteed.

One day I got tired of that and threw this together in a couple of hours:

It clamps to the quill of the vertical mill and holds a $20 Harbor Freight trim router. All functions of the mill are preserved, X, Y, Z and quill downfeed. My problems with small router cutters were solved. The original intention was to check feasibility and then make a permanent metal holder. But, since it DOES work, motivation has been low. Maybe I'll paint it someday, LOL.

I was doing some work on a friend’s bathrooms, adding small custom molding around mirrors and tiles. He had a table saw and a drill and that was the extent of his woodworking tools.

I made this little portable rig to accommodate another cheap trim router so that I could make the molding on site. It clamps to any convenient flat surface. (A fence is easily fashioned by clamping a straight piece of stock to the table.)

I hope that this long post doesn’t violate any forum policy. This is partly a response to fc350a it also illustrates a few projects although they weren’t recent ones.

Cheers,

randyc

P.S. As of this date, I have NINE routers - I just hate to change cutters so there is a different one in each - but most are never used. My father-in-law, 93 years old and going strong, who is also a woodworker, hangs out at garage sales and picks up a router every time he sees one. Between the two of us, we must have twenty of them. But ninety percent of the time the ones that I use these days is a 3.5 horsepower Milwaukee on a table and the two little trim routers, ha-ha-ha. Seems like I've almost come full circle -