11-30-2016, 12:03 AM

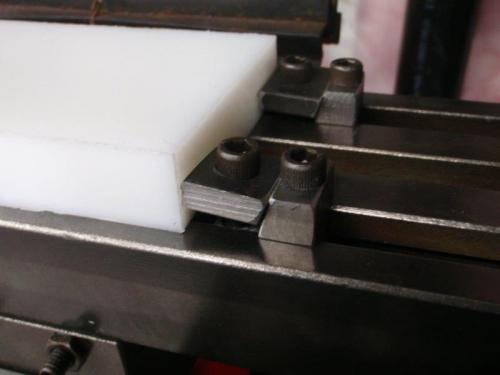

As it happens, aRM, I got the low profile clamps and accompanying bar done today. The T-nuts that form the base of the clamps had to be limited to 15/16" long so that they could fit in through the end trays on the table. The block that acts to clamp the unit to the table has a 15* slope to one side. When the clamping bar is tightened down, the end slides down this slope, causing the bar to move tighter into the work as it is being pulled down to the table. There is a sharp ridge on the work end of the bar that digs into the work, in this case, a block of plastic.

Meanwhile, at the other end of the work piece, the anchor bar has a sharp edge that bites into the work as it is pushed by the clamp bar.

This block will be used on the CNC mill to make ten water sensors when I get all of the G-code steps tweaked out. (And a few more design issues sorted out.)

Some day, I'll probably make a pair of new clamp bars out of tool steel and heat treat them to work with steel. For now, these ones will do fine for the plastic and possibly aluminum.

Meanwhile, at the other end of the work piece, the anchor bar has a sharp edge that bites into the work as it is pushed by the clamp bar.

This block will be used on the CNC mill to make ten water sensors when I get all of the G-code steps tweaked out. (And a few more design issues sorted out.)

Some day, I'll probably make a pair of new clamp bars out of tool steel and heat treat them to work with steel. For now, these ones will do fine for the plastic and possibly aluminum.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.