11-28-2016, 12:40 AM

Today I got to wondering whether the trouble I had yesterday with the Mach 3 display advancing a LOT faster than the table was moving while I was controlling it from the keyboard or pendant would go away when it was running from G-code.

Yup. Verily.

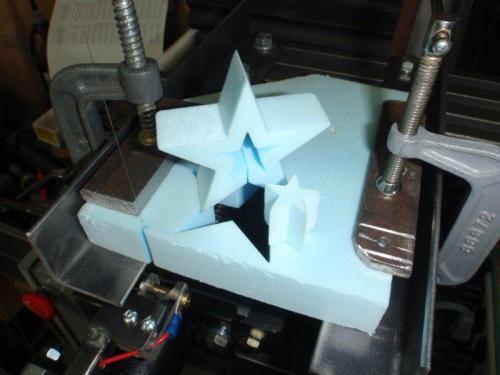

I restored all the motor settings I had been using before the fire and ran a routine I had written to test the hot-wire attachment I had made for it. Here's the result back then:

Today, I printed out the original drawing to scale and measured it against the design dimensions. Accurate to the nearest thou. I attached the drawing to the table and lined up a pointer in the spindle. It traced the line perfectly.

So now it's worth pressing ahead with designing all the thingies that this machine can make easiest. I also have to make a new hot-wire attachment. I told the 'restoration' company I wanted it back, but they obviously threw it out. The hot-wire will be a great tool for prepping for lost-foam castings.

Yup. Verily.

I restored all the motor settings I had been using before the fire and ran a routine I had written to test the hot-wire attachment I had made for it. Here's the result back then:

Today, I printed out the original drawing to scale and measured it against the design dimensions. Accurate to the nearest thou. I attached the drawing to the table and lined up a pointer in the spindle. It traced the line perfectly.

So now it's worth pressing ahead with designing all the thingies that this machine can make easiest. I also have to make a new hot-wire attachment. I told the 'restoration' company I wanted it back, but they obviously threw it out. The hot-wire will be a great tool for prepping for lost-foam castings.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.