Like pretty much everyone who's ever had a round-column mill/drill, I got tired of getting my hand dirty on the leadscrew while locking or unlocking the Y-axis. When i started to plan it out, I realized it was a pretty quick project. I won't bore you with a step-by-step description.

Here's the finished product. I do have some 1" screw-on balls that I was planning to use on the end of the handle, but there isn't enough clearance against the base casting. I may put a slight bend in the handle to allow it, but it seems to work well as is.

Unlocked.

Locked.

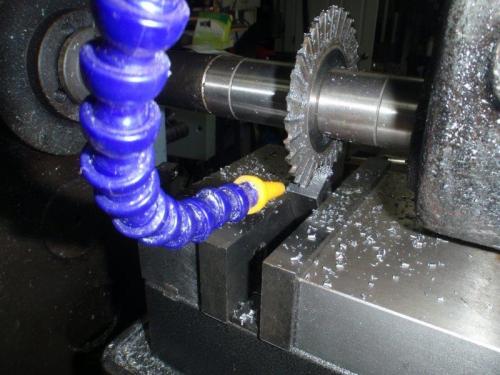

Okay. I'll give you one little detail. I cut the slots on the arms at 30 degrees to clear the link bar at both ends of travel. I clamped the bars at that angle and used one of my smallest slitting saws to make the cut.

I really like the way it works quick, clean and it really holds.

Here's the finished product. I do have some 1" screw-on balls that I was planning to use on the end of the handle, but there isn't enough clearance against the base casting. I may put a slight bend in the handle to allow it, but it seems to work well as is.

Unlocked.

Locked.

Okay. I'll give you one little detail. I cut the slots on the arms at 30 degrees to clear the link bar at both ends of travel. I clamped the bars at that angle and used one of my smallest slitting saws to make the cut.

I really like the way it works quick, clean and it really holds.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.