01-30-2016, 08:41 PM

I finally got around to shortening the DRO scale for the x axis. Measured, scribed and cut by hand with a hacksaw. The scale isn't as fragile as I had been lead to believe from the usual Google search and I can confirm that it will not explode if exposed to sunlight.

I supported the scale with a pair of long nose pliers and then nibbled at it with some small side cutters. The first nibble broke most of the waste piece off and it took one or two more to finish up. The scale is actually quite difficult to get to.

The most time consuming part of the process was drilling and tapping new screw holes into the extrusion. This is some low grade soft and gummy aluminium. I didn't have a M2 tap so had to go up to M3x0.5 The flexibility of a turret mill was appreciated during this process. I didn't have a counterbore to suite, so I simply milled the sections off the end block to suit.

set up for drilling

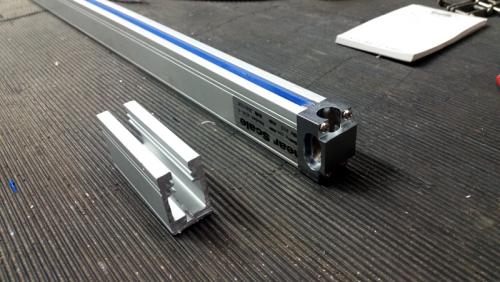

Finished, with the removed section and modified end block

A quick test showed that the scale read over the full range. Next is installing them

I supported the scale with a pair of long nose pliers and then nibbled at it with some small side cutters. The first nibble broke most of the waste piece off and it took one or two more to finish up. The scale is actually quite difficult to get to.

The most time consuming part of the process was drilling and tapping new screw holes into the extrusion. This is some low grade soft and gummy aluminium. I didn't have a M2 tap so had to go up to M3x0.5 The flexibility of a turret mill was appreciated during this process. I didn't have a counterbore to suite, so I simply milled the sections off the end block to suit.

set up for drilling

Finished, with the removed section and modified end block

A quick test showed that the scale read over the full range. Next is installing them

Hunting American dentists since 2015.