12-20-2015, 11:21 PM

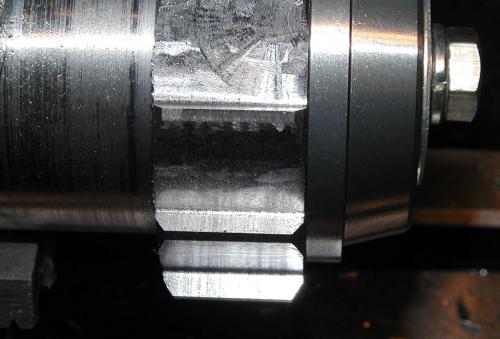

Worked on machining the new ratchet ring for my arbor press this weekend. I decided to try out the new 1" Valenite Center-Dex end mill I got thru Ken (Pixman). It seemed to do a fine job of removing metal - spitting out small, tightly curled, spiral cylinders of 4140 steel. I don't know what I did wrong, but I wasn't too keen on the finish I got so I will likely take additional finish cuts with a HSS end mill.

I used another piece of round stock to make an arbor for the rotary table to clamp the ring to in order to mill each cut in a single pass. I drilled and tapped one end 3/8-16. I got lucky and found a bearing race driver in my set that was the perfect diameter for holding the ring, and staying clear of the tool path. When finished cutting the teeth, I'll use the same piece of round stock to make a bushing for broaching a keyway in the ratchet ring.

And then comes the heat treating....

I used another piece of round stock to make an arbor for the rotary table to clamp the ring to in order to mill each cut in a single pass. I drilled and tapped one end 3/8-16. I got lucky and found a bearing race driver in my set that was the perfect diameter for holding the ring, and staying clear of the tool path. When finished cutting the teeth, I'll use the same piece of round stock to make a bushing for broaching a keyway in the ratchet ring.

And then comes the heat treating....

Willie