11-29-2015, 05:35 PM

I think I have a Bit of catching up to do.

having prepared the blanks the combustion chambers where formed .

Then the mill head was tilted 45° and the holes for the plugs drilled

The head was then flipped over and the counter bore cut and the hole tapped.

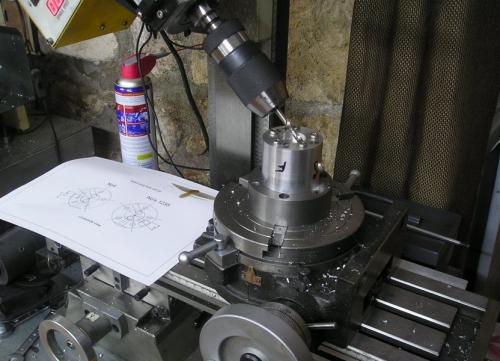

After tramming the mill the jig was set up to drill --bore and counter bore the holes for the valve cages.

The second hole was set up by simply turning the table 180°

Note that the head at the front has the spark plug on the opposite side, this is #4 cylinder and it is done to keep the plug away from the oil that drains down when the engine is stationary.

Brian

having prepared the blanks the combustion chambers where formed .

Then the mill head was tilted 45° and the holes for the plugs drilled

The head was then flipped over and the counter bore cut and the hole tapped.

After tramming the mill the jig was set up to drill --bore and counter bore the holes for the valve cages.

The second hole was set up by simply turning the table 180°

Note that the head at the front has the spark plug on the opposite side, this is #4 cylinder and it is done to keep the plug away from the oil that drains down when the engine is stationary.

Brian