11-08-2015, 05:27 AM

The first cylinder was made to prove the jigs . the remaining 4 will be made as a batch to save time and effort.

First the blank is prepared to fit the jig.

Then the holes for the studs are drilled.

And the fins cut.

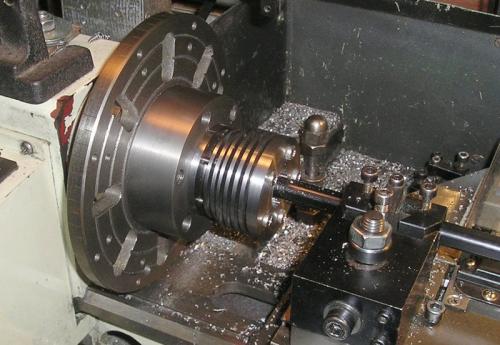

the jig and cylinder is then put on the lathe and the bore roughed out.

and the taper of the fins done.

Final finishing to be done later

Brian

First the blank is prepared to fit the jig.

Then the holes for the studs are drilled.

And the fins cut.

the jig and cylinder is then put on the lathe and the bore roughed out.

and the taper of the fins done.

Final finishing to be done later

Brian