07-22-2015, 09:44 AM

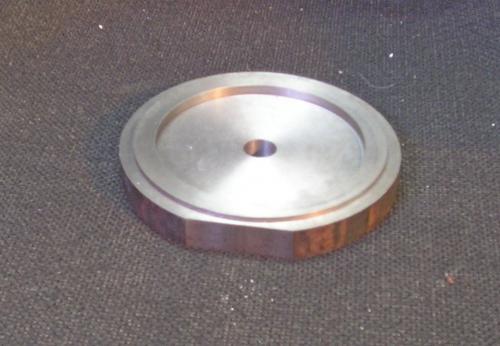

The next stage was to machine the jig base-the central hole for the spigot and the 90 mm register being machined without disturbing the work to ensure concentricity. I have ordered two soft arbours MT3 for the lathe and MT2 for the rotary table

to be machined 12mm to fit the central spigot.

Photo shows the work so far with the conversion ring in place.

The next problem is to hold the jig and the work radially, so when a part is placed in the jig 0° is always correct.

To this end I have made new T slot nuts for the rotary table that fit perfectly and the threads are on centre and straight,

The holes in the jig will be sized to just take the bolts. I think this will solve the problem of locating the jig the work will be retained by a centre draw bar and 5 studs that locate in the position of the accessory shafts.

Slowly slowly, Brian.

to be machined 12mm to fit the central spigot.

Photo shows the work so far with the conversion ring in place.

The next problem is to hold the jig and the work radially, so when a part is placed in the jig 0° is always correct.

To this end I have made new T slot nuts for the rotary table that fit perfectly and the threads are on centre and straight,

The holes in the jig will be sized to just take the bolts. I think this will solve the problem of locating the jig the work will be retained by a centre draw bar and 5 studs that locate in the position of the accessory shafts.

Slowly slowly, Brian.