07-14-2015, 02:12 PM

With the sounding of trumpets and the beating of drums the first material was cut today.

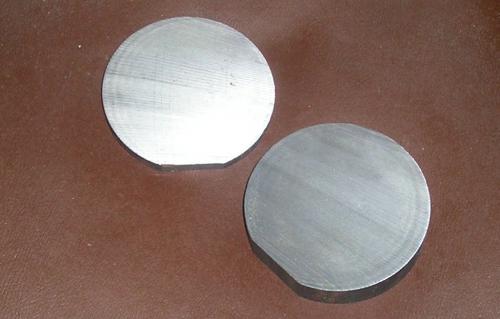

These two disks will form the Jig for all the crank case work, the engine has been designed so that all the sections have the same diameter registers, also the jig will be transferable between the rotary table and the lathe face plate, located by a central spigot, so set up time will be kept to the minimum.

I can just get the 100mm blank into my 4 jaw self centring chuck so work will start tomorrow,

Up Up and away Brian

These two disks will form the Jig for all the crank case work, the engine has been designed so that all the sections have the same diameter registers, also the jig will be transferable between the rotary table and the lathe face plate, located by a central spigot, so set up time will be kept to the minimum.

I can just get the 100mm blank into my 4 jaw self centring chuck so work will start tomorrow,

Up Up and away Brian