Hi All

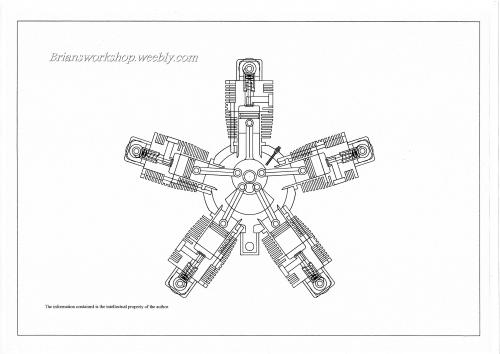

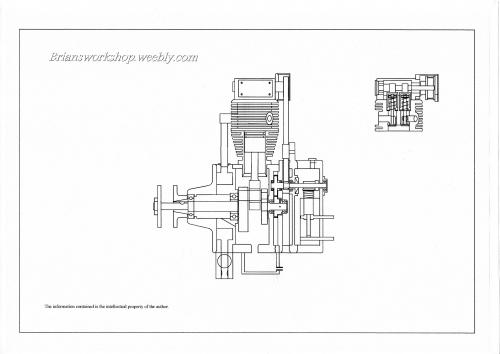

After long hours at the computer the working drawings are coming together, it's amazing what you have to change to accommodate fixing screws etc as I go along.

The engine mounts are now built into the design so they don't look like an after thought. also I am also working on the jigs necessary. and trying to make them multi use. for the lathe and mill.

I have settled on having Individual hall sensors on each cam and separate mini coils so perhaps later by using two magnets I will be able to have auto advance.

As some of you will know The master rod causes timing problems on radial engines because only number one big end follows a circular path. all the others are slightly out at TDC ( not exactly 170° apart ) I am hoping that using separate cam shafts I will be able to get the valve and ignition timing correct .

Tooling for the lathe and mill is under review , a co axial indicator for the mill will be the on the cards.

Brian.

After long hours at the computer the working drawings are coming together, it's amazing what you have to change to accommodate fixing screws etc as I go along.

The engine mounts are now built into the design so they don't look like an after thought. also I am also working on the jigs necessary. and trying to make them multi use. for the lathe and mill.

I have settled on having Individual hall sensors on each cam and separate mini coils so perhaps later by using two magnets I will be able to have auto advance.

As some of you will know The master rod causes timing problems on radial engines because only number one big end follows a circular path. all the others are slightly out at TDC ( not exactly 170° apart ) I am hoping that using separate cam shafts I will be able to get the valve and ignition timing correct .

Tooling for the lathe and mill is under review , a co axial indicator for the mill will be the on the cards.

Brian.