06-26-2015, 08:51 AM

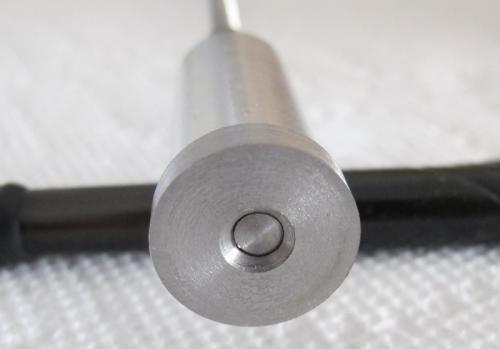

A friend wants me to weld threaded rods to a steel discs, despite telling him I suck at welding. These will be feet for some device, I'm not sure what. So in order to have a chance in hell at accomplishing this task I need some help in setting up the welder for this situation. The threaded rod is 10-24 mild steel and the disk is about 3/4" in diameter by about 1/4" thick made of CRS. I've got a piece of aluminum held up against the underside of the disc to keep the disc at a right angle to the threaded rod. I countersunk the disk so I can fill it in with weld. There's not going to be a lot of pressure on these so if I can get a reasonable amount of weld to hold them together, it should be fine for his application. The weld will be faced off on the lathe after welding.

I don't want to blow through the disc and/or rod so any tips would be appreciated.

Do you think I need to use .025 wire instead of .030?

Ed

I don't want to blow through the disc and/or rod so any tips would be appreciated.

Do you think I need to use .025 wire instead of .030?

Ed