05-23-2015, 11:55 PM

With the power sorted out I pressed the green button and the motor started up. The motor itself is quiet but the oil pump is a little noisy. However, as it circulated the oil is quietened down a little. I let it run for a little while before spinning up the chuck, waiting until I could see oil splashing about in the sight glass.

Now, here is my problem. When I looked at the lathe, I was able to drive the feedshaft from the feedbox, and it rotated as normal. Now, I cannot get it to drive, despite changing the selection levers (ensuring that the one for the feedshaft is selected). Further, one of the levers no longer engages into two of its positions. I'm wondering if something has come loose on the trip up? I really don't want to pull the feedbox to find that something has terminally failed.

I tried to push that to the back of my mind, whilst deciding to open up the headstock and set about adjusting the clutches.

Once I had unscrewed the back access panel I discovered that the inside lip holds a fair bit of oil! Given the location of the panel, it ensured that any oil runs into the electrical box and then from there into the motor housing

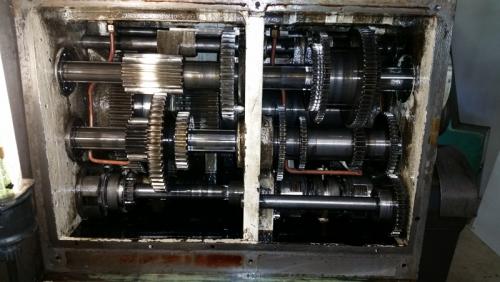

Once off I had a quick visual inspection and was very pleased not to see any signs of broken teeth or other damage.This is much more complicated than my old mill...

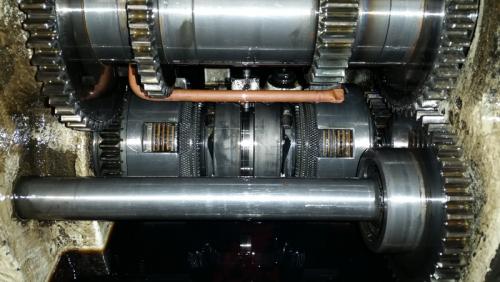

The spindle break clutch. Should activate whenever the drive clutches are released.

The drive clutches. Forward drive is on the left and the reversed drive is on the right.

As I had to work last night, I decided to leave the clutch adjustment until today.

Now, here is my problem. When I looked at the lathe, I was able to drive the feedshaft from the feedbox, and it rotated as normal. Now, I cannot get it to drive, despite changing the selection levers (ensuring that the one for the feedshaft is selected). Further, one of the levers no longer engages into two of its positions. I'm wondering if something has come loose on the trip up? I really don't want to pull the feedbox to find that something has terminally failed.

I tried to push that to the back of my mind, whilst deciding to open up the headstock and set about adjusting the clutches.

Once I had unscrewed the back access panel I discovered that the inside lip holds a fair bit of oil! Given the location of the panel, it ensured that any oil runs into the electrical box and then from there into the motor housing

Once off I had a quick visual inspection and was very pleased not to see any signs of broken teeth or other damage.This is much more complicated than my old mill...

The spindle break clutch. Should activate whenever the drive clutches are released.

The drive clutches. Forward drive is on the left and the reversed drive is on the right.

As I had to work last night, I decided to leave the clutch adjustment until today.

Hunting American dentists since 2015.