Hi,

OK, first off I am sorry for taking so long but I have been busy and for the last 2-3 nights I have come up from the shed and read the forum and thought, oh crap I didn't take the photos. So tonight I took a special trip back down.

Now this is not the way they sharpen slitting saws as they do it on the front face, but if you have nowhere to get them sharpened and it's just rubbish as it's blunt I think you should try this as I think it will work.

Like I said in my first post this is to sharpen a woodruff key cutter, but I don't see why it wouldn't work on a slitting saw.

One woodruff cutter I bought off ebay was advertised as new, but when I got it, it was just re sharpened. It did the job but never ran true always cutting on a few teeth. After I re sharpened it I had no problems at all, and it cut on all teeth evenly as far as I could tell.

I don't know your level of machining etc, but have just done a right up for everyone from beginner up to understand, because hopefully it will help others as well.

Now on with it.

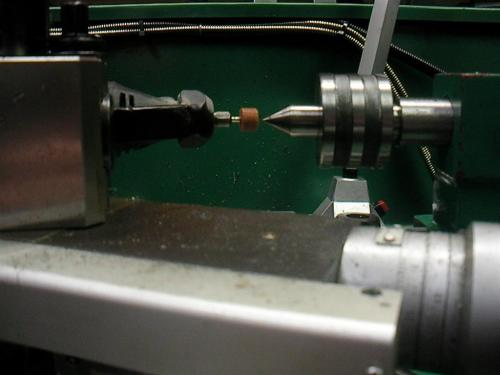

This is my dremel set up, just a nut welded to a bit of flat bar that fits in my tool post.

Start by mounting the Dremel and turning it around to make sure it's on centre using the tailstock with a centre in it.

Then spin it back around at 90 degrees to the chuck and true the stone with a diamond dresser. The dressers are cheap and this really needs to be done to get rid of as much vibration as possible and true the stone up.

Just make sure you cover the lathe bed up from the grinding dust.

Clamp a piece of flat bar to the back of the bed as shown and use a piece of wood or something similar at the front so the clamp doesn't damage you lathe way.

Make sure the front edge of the flat bar is in line with the front of the cutter to be sharpened, this will help with alignment latter if the flat bar happens to get dropped it can go back in the same spot.

You can see I have the cutter in a 3 jaw chuck, my 3 jaw is back plate mounted and has the register machined slightly smaller so I can make it run accurate. When I sharpen cutters I make sure it's running true with a dial indicator. If yours is not adjustable, use a 4 jaw chuck and dial it in. If it's out your cutter will have run out.

Next cut a piece of flat bar to go from the corner of the flat bar and the lathe bed to the cutter tooth. Any tooth is good enough as long as it fits neatly. Just make sure you file off all sharp edges so it doesn't mark the bed in any way.

You can see in this picture how the flat bar is cut to the right length to fit into the tooth neatly.

Next I use a marker to colour in the land (see below) so I can see where the grinder is touching. Since yours is a slitting saw it wont have one, so you will need to grind it lightly and check the angle (again see below), but you will only need a touch on each tooth to sharpen it the first time.

I also mark the tooth I am starting on so I know when I am finished a rotation.

I adjust the tool holder up or down to suit the land angle and once it's set I wind in the cross feed a little and take a light cut by moving the carriage in toward the chuck and back out again, and then while holding the flat bar up I rotate the cutter backwards so it drops into the next tooth and then make sure it's seated properly by rotating it forward. move to the next tooth and so on until they are all done.

Just make sure you cover the lathe bed up from the grinding dust.

As long as they are light cuts the stone wont change in diameter so every tooth will be the same. If you have a chipped tooth or need more off, just around around again until you have it right, but only light cuts.

This picture below shows you the angles of the land etc. The easiest way I found to check the angle is to find a washer that the cutter fits in and eye it up. With something larger like a slitting saw you could just wrap a piece of thin aluminium around a few teeth and eye it up like that. They don't need to be perfect to give good results.

Like I said I have only done woodruff cutters, but I will be trying it on slitting saws myself since it works so good with these. Taking a slitting saw to get sharpened around here is more expensive than buying a new one, so I think it's worth a try and think it will work as it's only taking a tiny amount off.

Dave

PS

This has taken longer to right than what it does to do the job, LOL

OK, first off I am sorry for taking so long but I have been busy and for the last 2-3 nights I have come up from the shed and read the forum and thought, oh crap I didn't take the photos. So tonight I took a special trip back down.

Now this is not the way they sharpen slitting saws as they do it on the front face, but if you have nowhere to get them sharpened and it's just rubbish as it's blunt I think you should try this as I think it will work.

Like I said in my first post this is to sharpen a woodruff key cutter, but I don't see why it wouldn't work on a slitting saw.

One woodruff cutter I bought off ebay was advertised as new, but when I got it, it was just re sharpened. It did the job but never ran true always cutting on a few teeth. After I re sharpened it I had no problems at all, and it cut on all teeth evenly as far as I could tell.

I don't know your level of machining etc, but have just done a right up for everyone from beginner up to understand, because hopefully it will help others as well.

Now on with it.

This is my dremel set up, just a nut welded to a bit of flat bar that fits in my tool post.

Start by mounting the Dremel and turning it around to make sure it's on centre using the tailstock with a centre in it.

Then spin it back around at 90 degrees to the chuck and true the stone with a diamond dresser. The dressers are cheap and this really needs to be done to get rid of as much vibration as possible and true the stone up.

Just make sure you cover the lathe bed up from the grinding dust.

Clamp a piece of flat bar to the back of the bed as shown and use a piece of wood or something similar at the front so the clamp doesn't damage you lathe way.

Make sure the front edge of the flat bar is in line with the front of the cutter to be sharpened, this will help with alignment latter if the flat bar happens to get dropped it can go back in the same spot.

You can see I have the cutter in a 3 jaw chuck, my 3 jaw is back plate mounted and has the register machined slightly smaller so I can make it run accurate. When I sharpen cutters I make sure it's running true with a dial indicator. If yours is not adjustable, use a 4 jaw chuck and dial it in. If it's out your cutter will have run out.

Next cut a piece of flat bar to go from the corner of the flat bar and the lathe bed to the cutter tooth. Any tooth is good enough as long as it fits neatly. Just make sure you file off all sharp edges so it doesn't mark the bed in any way.

You can see in this picture how the flat bar is cut to the right length to fit into the tooth neatly.

Next I use a marker to colour in the land (see below) so I can see where the grinder is touching. Since yours is a slitting saw it wont have one, so you will need to grind it lightly and check the angle (again see below), but you will only need a touch on each tooth to sharpen it the first time.

I also mark the tooth I am starting on so I know when I am finished a rotation.

I adjust the tool holder up or down to suit the land angle and once it's set I wind in the cross feed a little and take a light cut by moving the carriage in toward the chuck and back out again, and then while holding the flat bar up I rotate the cutter backwards so it drops into the next tooth and then make sure it's seated properly by rotating it forward. move to the next tooth and so on until they are all done.

Just make sure you cover the lathe bed up from the grinding dust.

As long as they are light cuts the stone wont change in diameter so every tooth will be the same. If you have a chipped tooth or need more off, just around around again until you have it right, but only light cuts.

This picture below shows you the angles of the land etc. The easiest way I found to check the angle is to find a washer that the cutter fits in and eye it up. With something larger like a slitting saw you could just wrap a piece of thin aluminium around a few teeth and eye it up like that. They don't need to be perfect to give good results.

Like I said I have only done woodruff cutters, but I will be trying it on slitting saws myself since it works so good with these. Taking a slitting saw to get sharpened around here is more expensive than buying a new one, so I think it's worth a try and think it will work as it's only taking a tiny amount off.

Dave

PS

This has taken longer to right than what it does to do the job, LOL