Made a start on the big end bearing ,

I have never made a split shell bearing so this is well outside my comfort zone.

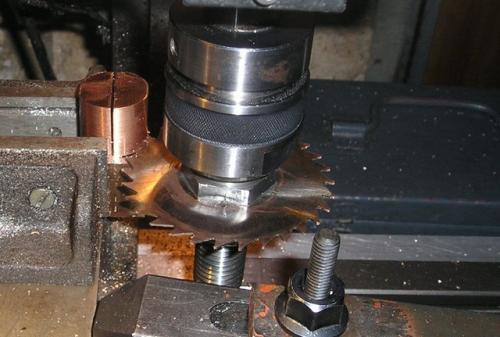

first job was to split the material in half on the mill using the slitting saw.

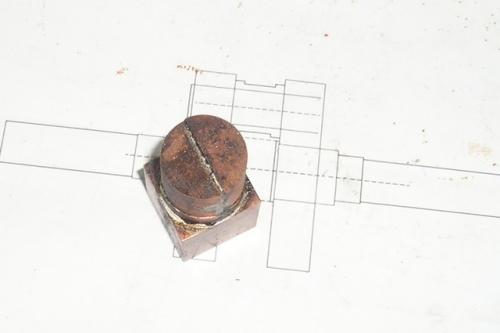

Then solder the two parts back together again.

I then turned the max OD this will be the size across the side thrust flanges, then bored the bearing bore, my boring bar was to large for this job so I used the mill boring head in the tail stock.

More later I am getting twitchy.

Brian.

I have never made a split shell bearing so this is well outside my comfort zone.

first job was to split the material in half on the mill using the slitting saw.

Then solder the two parts back together again.

I then turned the max OD this will be the size across the side thrust flanges, then bored the bearing bore, my boring bar was to large for this job so I used the mill boring head in the tail stock.

More later I am getting twitchy.

Brian.