05-11-2012, 12:04 PM

(This post was last modified: 05-11-2012, 12:06 PM by henryarnold.)

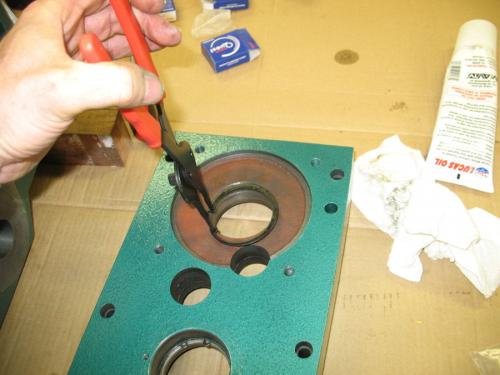

In this post I'll show installation of the quill seal plate. Earlier I showed installation of the seals in this plate.

Originally the plate had just a gasket but since I am suspicious that a leak past this plate may have occurred, I use Permatex #2 on both the mounting surface and the plate. During installation the gasket squeezed out of place which is not good. I may have assembled it too soon. I'm not recommending this but I decided to leave the gasket out and to just use the Permatex. My mounting surface has a very thin edge near the 2nd Intermediate Shaft and I feel that the gasket could not be relied on to stay on that thin surface.

Throughout the reassembly I have replaced questionable hardware. These are new quality screws that I'm using to install the seal plate.

I decided to grease the seals concentrating on getting some grease between the two seals. My reasoning is that if the first seal does its job, no oil will reach the second seal and it will be running dry. I may be totally wrong on this.

Install the 3 circlips in the lid. There is one large one for the motor shaft bearing and two smaller ones for the intermediate shafts. I did not remove the circlip that was in the spindle shaft bore. You can see in the photo that its in place. The spindle shaft bor also has a spacer which I did not remove.

Originally the plate had just a gasket but since I am suspicious that a leak past this plate may have occurred, I use Permatex #2 on both the mounting surface and the plate. During installation the gasket squeezed out of place which is not good. I may have assembled it too soon. I'm not recommending this but I decided to leave the gasket out and to just use the Permatex. My mounting surface has a very thin edge near the 2nd Intermediate Shaft and I feel that the gasket could not be relied on to stay on that thin surface.

Throughout the reassembly I have replaced questionable hardware. These are new quality screws that I'm using to install the seal plate.

I decided to grease the seals concentrating on getting some grease between the two seals. My reasoning is that if the first seal does its job, no oil will reach the second seal and it will be running dry. I may be totally wrong on this.

Install the 3 circlips in the lid. There is one large one for the motor shaft bearing and two smaller ones for the intermediate shafts. I did not remove the circlip that was in the spindle shaft bore. You can see in the photo that its in place. The spindle shaft bor also has a spacer which I did not remove.

henryarnold, proud to be a member of MetalworkingFun Forum since Apr 2012.