10-06-2014, 04:13 PM

Hi all sorry to have been away so long, but I have had a good summer sailing, then a computer failure that cost me dear, so iv'e got a lot of catching up to do.

I have managed some time in the shop in between so this is the story so far.

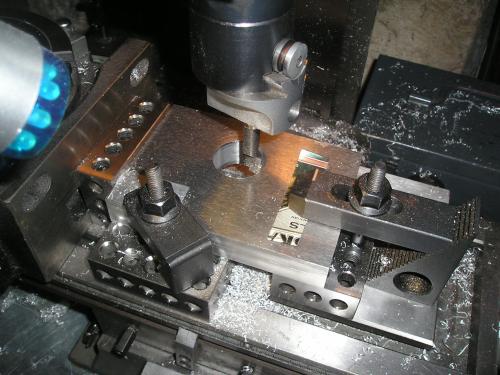

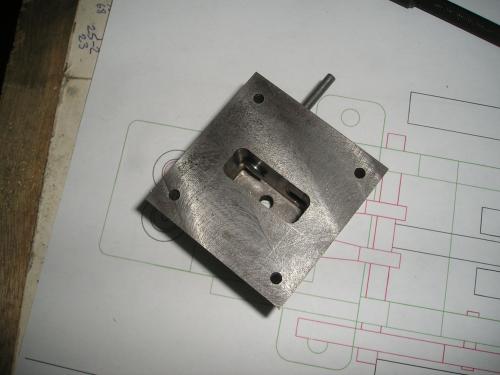

the crank case was cut from 10mm plate and machined.

all the fixing holes were drilled using the X Y dro's on the mill it was strange drilling 44 holes without marking out, the came the trial assembly--- Magic all the holes lined up perfectly.

the plastic pipe is to test the alignment.

The head has had a lot of work --milling the combustion chamber--drilling the ports and valve guides- cutting the fins ETC.

The valves are from stainless steel.

It's coming along nicely, more later

Brian.

I have managed some time in the shop in between so this is the story so far.

the crank case was cut from 10mm plate and machined.

all the fixing holes were drilled using the X Y dro's on the mill it was strange drilling 44 holes without marking out, the came the trial assembly--- Magic all the holes lined up perfectly.

the plastic pipe is to test the alignment.

The head has had a lot of work --milling the combustion chamber--drilling the ports and valve guides- cutting the fins ETC.

The valves are from stainless steel.

It's coming along nicely, more later

Brian.