08-04-2014, 03:58 PM

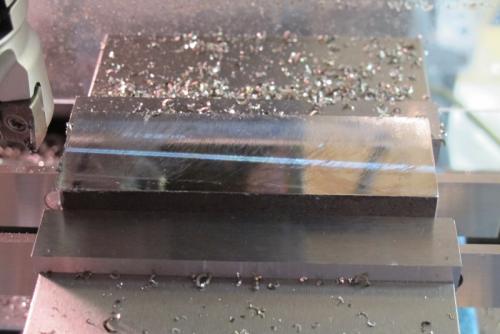

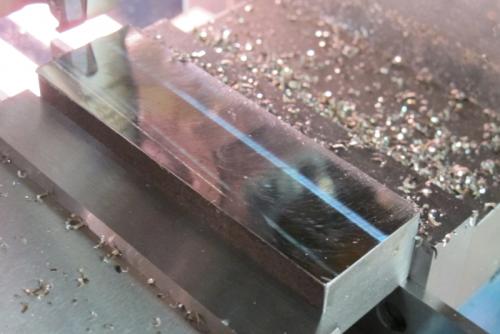

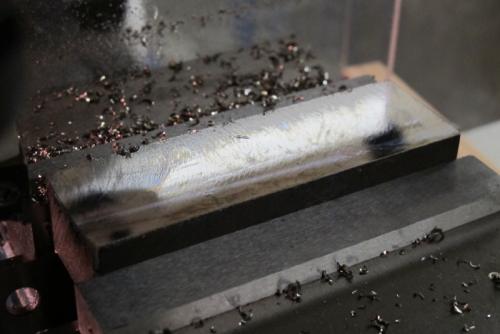

I thought I'd post pictures of the first pass. It looks worse in the pictures than in real life, at least I think so. The mill was noisier than usual and I don't know if it's from the bearings or the gears. I'll do one more pass on this side and then flip it and mill it to dimension, assuming the mill hangs in there.

I know for an end mill it's advised to cut half the diameter of the end mill in one pass. Does that apply to a tool like I'm using now?

Ed

I know for an end mill it's advised to cut half the diameter of the end mill in one pass. Does that apply to a tool like I'm using now?

Ed