The next job was to cut the 45° space for the "O"ring.

Then the assembled barrel and liner was set up in the mill To finish the bore. It took a lot of passes to get the taper out of the bore caused by the tool springing. I am so glad I modded the X to power feed.

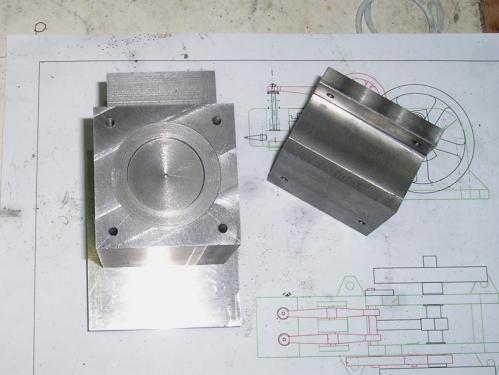

The piston was then turned to size and lapped to fit.

Rings to get, and grooves to cut, then it can come off the mandrel to do the inside.

Brian.

Then the assembled barrel and liner was set up in the mill To finish the bore. It took a lot of passes to get the taper out of the bore caused by the tool springing. I am so glad I modded the X to power feed.

The piston was then turned to size and lapped to fit.

Rings to get, and grooves to cut, then it can come off the mandrel to do the inside.

Brian.